Chapter 29 Shielded Metal Arc Welding 815

Copyright Goodheart-Willcox Co., Inc.

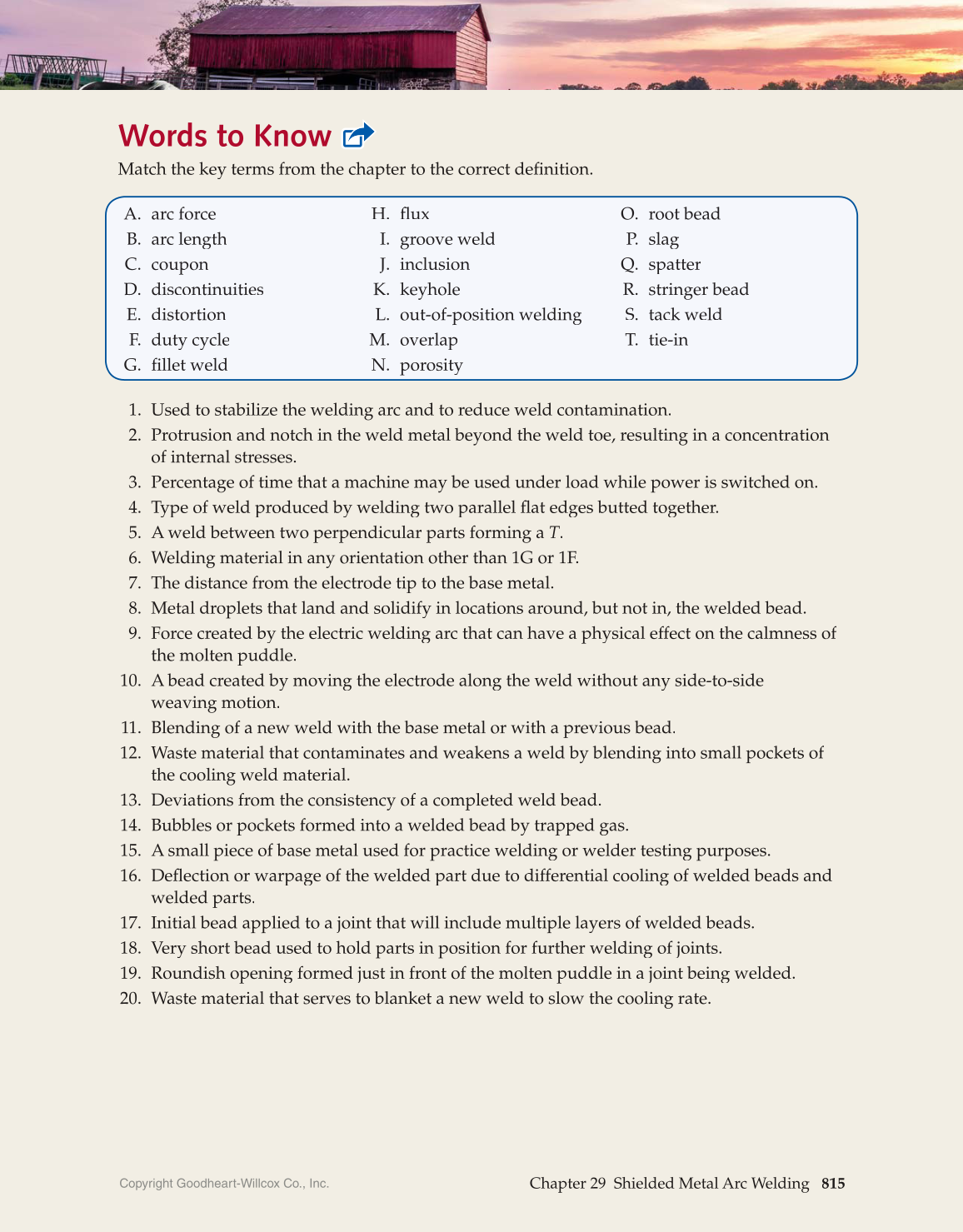

Words to Know

Match the key terms from the chapter to the correct definition.fi

A. arc force

B. arc length

C. coupon

D. discontinuities

E. distortion

F. duty cycle

G. fi llet weld fi

H. fl ux fl

I. groove weld

J. inclusion

K. keyhole

L. out-of-position welding

M. overlap

N. porosity

O. root bead

P. slag

Q. spatter

R. stringer bead

S. tack weld

T. tie-in

1. Used to stabilize the welding arc and to reduce weld contamination.

2. Protrusion and notch in the weld metal beyond the weld toe, resulting in a concentration

of internal stresses.

3. Percentage of time that a machine may be used under load while power is switched on.

4. Type of weld produced by welding two parallel fl at edges butted together. fl

5. A weld between two perpendicular parts forming a T.

6. Welding material in any orientation other than 1G or 1F.

7. The distance from the electrode tip to the base metal.

8. Metal droplets that land and solidify in locations around, but not in, the welded bead.

9. Force created by the electric welding arc that can have a physical effect on the calmness of

the molten puddle.

10. A bead created by moving the electrode along the weld without any side-to-side

weaving motion.

11. Blending of a new weld with the base metal or with a previous bead.

12. Waste material that contaminates and weakens a weld by blending into small pockets of

the cooling weld material.

13. Deviations from the consistency of a completed weld bead.

14. Bubbles or pockets formed into a welded bead by trapped gas.

15. A small piece of base metal used for practice welding or welder testing purposes.

16. Defl or warpage of the welded part due to differential cooling of welded beads and flection

welded parts.

17. Initial bead applied to a joint that will include multiple layers of welded beads.

18. Very short bead used to hold parts in position for further welding of joints.

19. Roundish opening formed just in front of the molten puddle in a joint being welded.

20. Waste material that serves to blanket a new weld to slow the cooling rate.