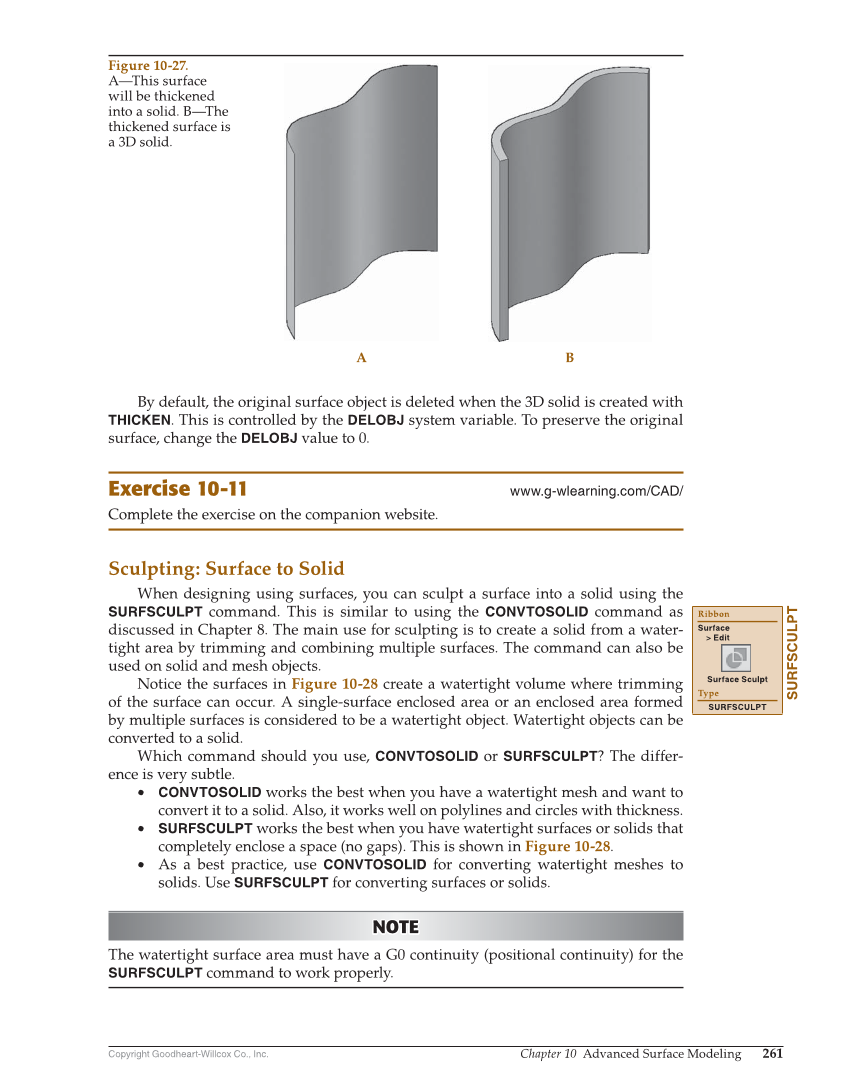

Copyright Goodheart-Willcox Co., Inc. Chapter 10 Advanced Surface Modeling 261 By default, the original surface object is deleted when the 3D solid is created with THICKEN. This is controlled by the DELOBJ system variable. To preserve the original surface, change the DELOBJ value to 0. Exercise 10-11 www.g-wlearning.com/CAD/ Complete the exercise on the companion website. Sculpting: Surface to Solid When designing using surfaces, you can sculpt a surface into a solid using the SURFSCULPT command. This is similar to using the CONVTOSOLID command as discussed in Chapter 8. The main use for sculpting is to create a solid from a water- tight area by trimming and combining multiple surfaces. The command can also be used on solid and mesh objects. Notice the surfaces in Figure 10-28 create a watertight volume where trimming of the surface can occur. A single-surface enclosed area or an enclosed area formed by multiple surfaces is considered to be a watertight object. Watertight objects can be converted to a solid. Which command should you use, CONVTOSOLID or SURFSCULPT? The differ- ence is very subtle. • CONVTOSOLID works the best when you have a watertight mesh and want to convert it to a solid. Also, it works well on polylines and circles with thickness. • SURFSCULPT works the best when you have watertight surfaces or solids that completely enclose a space (no gaps). This is shown in Figure 10-28. • As a best practice, use CONVTOSOLID for converting watertight meshes to solids. Use SURFSCULPT for converting surfaces or solids. NOTE NOTE The watertight surface area must have a G0 continuity (positional continuity) for the SURFSCULPT command to work properly. SURFSCULPT Ribbon Surface Edit Surface Sculpt Type SURFSCULPT A B Figure 10-27. A—This surface will be thickened into a solid. B—The thickened surface is a 3D solid.