156 Modern Commercial Wiring

Copyright Goodheart-Willcox Co., Inc.

5. Compute receptacle outlets as follows:

• Receptacles as 180VA each. (Section 220.14(I))

• Multioutlet assemblies at 180 VA per each 5′

portion. (Section 220.14(H)(1))

• Show windows at either of the following (Section

220.14(G)):

(1) The unit load per outlet as required in

other provisions of Section 220.14

(2) At 200 VA per 300 mm (1 foot) of show

window

• Heavy-duty lamp holders at 600 VA each.

(Section 220.14(E))

• Others as outlined in Section 220.14

6. Apply any of the demand factors as shown in Table

220.44 for receptacle loads and Table 220.56 for

kitchen equipment loads.

7. Add the sign lighting load (1200 VA minimum).

(Section 220.14(F))

8. Compute the motor loads using the appropriate tables

in Article 430.

9. Increase largest motor load based on full-load current

by 25%. (Section 430.24)

10. Size the service and service conductors. Compute by

dividing the total load by the line voltage. Conductor

size is selected from Table 310.15(B)(16).

11. Using the guideline given in Section 250.24(C), size

the grounded service conductor. Be sure the grounded

service conductor is not smaller than the grounding

electrode conductor as given in Table 250.66.

12. Provided there is no discharge lighting, the neutral

load—if over 200 amperes—can be derated by 70%.

Refer to Section 220.61.

Sample Problems

The following examples represent a small sampling of

situations requiring computations to determine correct

sizing of equipment, conductors, overcurrent protection, and

other load demands encountered in commercial wiring. The

main purpose is to introduce the concept and give the reader

a general feel for the overall procedure. Numerous other

factors such as wiring methods, routing, distances, and

voltage drop (to name a few) have been purposefully

ignored here for the sake of simplicity. Still, by reviewing

and understanding these examples and the step-by-step

methodology, the commercial electrician, designer, engi-

neer, and student will be better equipped to move on to the

“real” calculations required in practical design situations.

The following problems illustrate load calculation

and feeder sizing for commercial structures:

• Small retail store—Sample Problem 12-12.

• Office building—Sample Problem 12-13.

• Restaurant—Sample Problem 12-14.

• Hotel—Sample Problem 12-15.

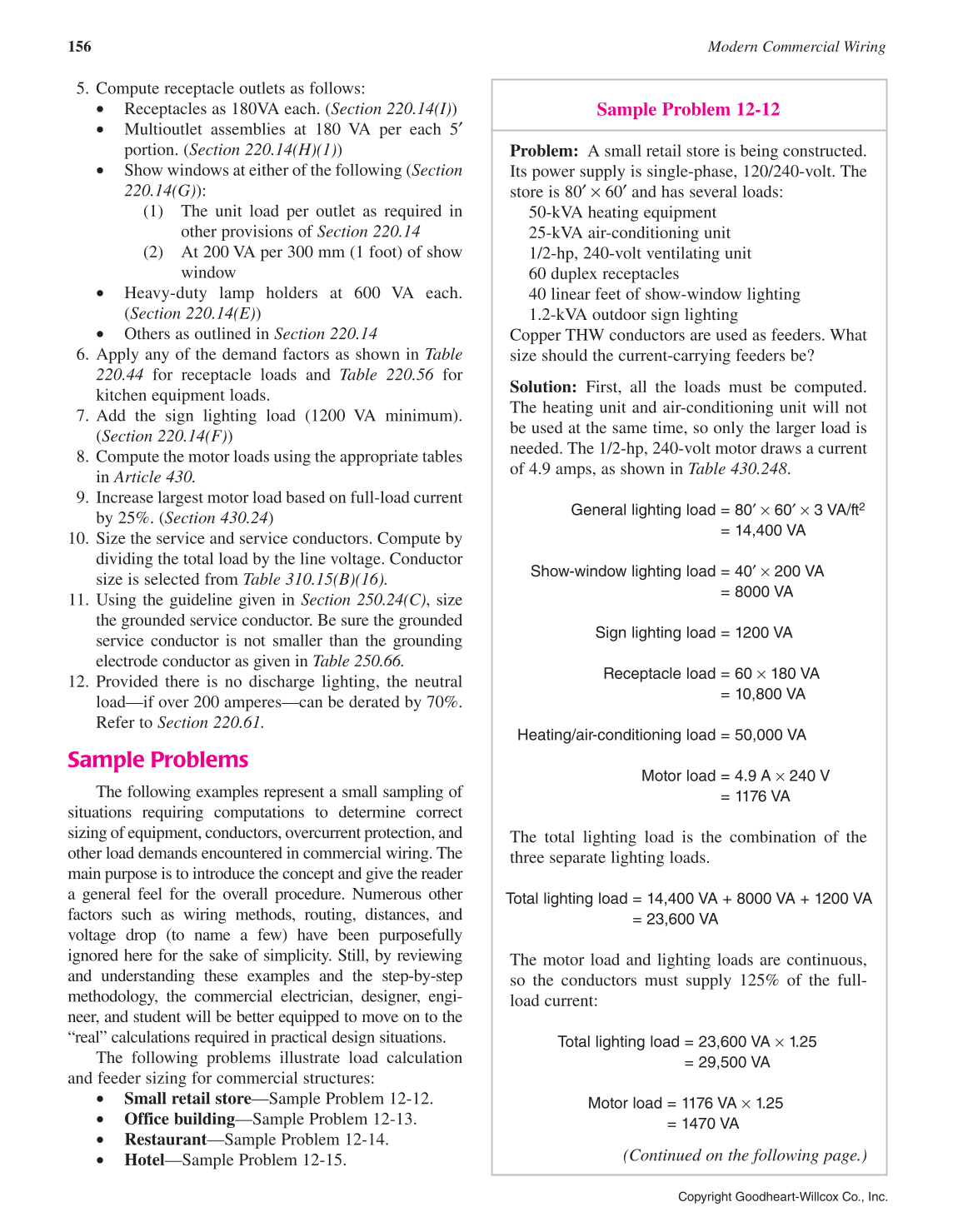

Sample Problem 12-12

Problem: A small retail store is being constructed.

Its power supply is single-phase, 120/240-volt. The

store is 80′ × 60′ and has several loads:

50-kVA heating equipment

25-kVA air-conditioning unit

1/2-hp, 240-volt ventilating unit

60 duplex receptacles

40 linear feet of show-window lighting

1.2-kVA outdoor sign lighting

Copper THW conductors are used as feeders. What

size should the current-carrying feeders be?

Solution: First, all the loads must be computed.

The heating unit and air-conditioning unit will not

be used at the same time, so only the larger load is

needed. The 1/2-hp, 240-volt motor draws a current

of 4.9 amps, as shown in Table 430.248.

General lighting load = 80′ × 60′ × 3 VA/ft2

= 14,400 VA

Show-window lighting load = 40′ × 200 VA

= 8000 VA

Sign lighting load = 1200 VA

Receptacle load = 60 × 180 VA

= 10,800 VA

Heating/air-conditioning load = 50,000 VA

Motor load = 4.9 A × 240 V

= 1176 VA

The total lighting load is the combination of the

three separate lighting loads.

Total lighting load = 14,400 VA + 8000 VA + 1200 VA

= 23,600 VA

The motor load and lighting loads are continuous,

so the conductors must supply 125% of the full-

load current:

Total lighting load = 23,600 VA × 1.25

= 29,500 VA

Motor load = 1176 VA × 1.25

= 1470 VA

(Continued on the following page.)