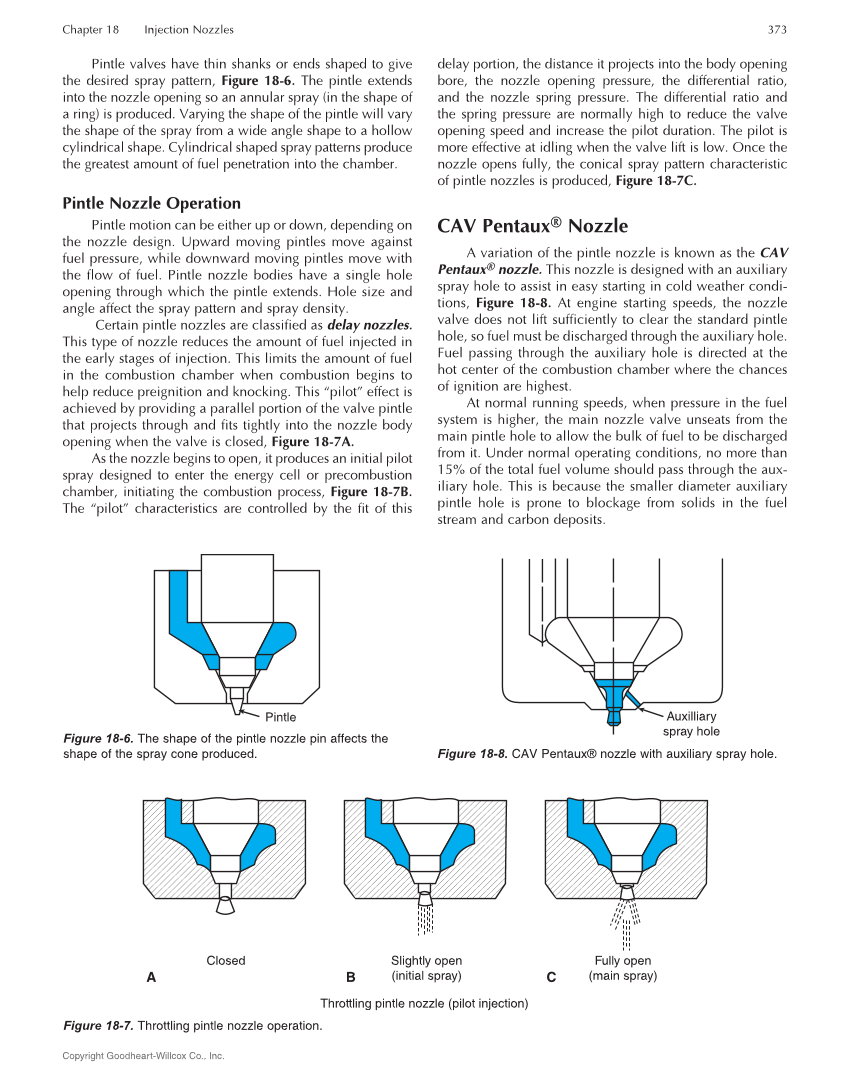

Chapter 18 Injection Nozzles 373 Copyright Goodheart-Willcox Co., Inc. Pintle valves have thin shanks or ends shaped to give the desired spray pattern, Figure 18-6. The pintle extends into the nozzle opening so an annular spray (in the shape of a ring) is produced. Varying the shape of the pintle will vary the shape of the spray from a wide angle shape to a hollow cylindrical shape. Cylindrical shaped spray patterns produce the greatest amount of fuel penetration into the chamber. Pintle Nozzle Operation Pintle motion can be either up or down, depending on the nozzle design. Upward moving pintles move against fuel pressure, while downward moving pintles move with the flow of fuel. Pintle nozzle bodies have a single hole opening through which the pintle extends. Hole size and angle affect the spray pattern and spray density. Certain pintle nozzles are classified as delay nozzles. This type of nozzle reduces the amount of fuel injected in the early stages of injection. This limits the amount of fuel in the combustion chamber when combustion begins to help reduce preignition and knocking. This “pilot” effect is achieved by providing a parallel portion of the valve pintle that projects through and fits tightly into the nozzle body opening when the valve is closed, Figure 18-7A. As the nozzle begins to open, it produces an initial pilot spray designed to enter the energy cell or precombustion chamber, initiating the combustion process, Figure 18-7B. The “pilot” characteristics are controlled by the fit of this delay portion, the distance it projects into the body opening bore, the nozzle opening pressure, the differential ratio, and the nozzle spring pressure. The differential ratio and the spring pressure are normally high to reduce the valve opening speed and increase the pilot duration. The pilot is more effective at idling when the valve lift is low. Once the nozzle opens fully, the conical spray pattern characteristic of pintle nozzles is produced, Figure 18-7C. CAV Pentaux® Nozzle A variation of the pintle nozzle is known as the CAV Pentaux® nozzle. This nozzle is designed with an auxiliary spray hole to assist in easy starting in cold weather condi- tions, Figure 18-8. At engine starting speeds, the nozzle valve does not lift sufficiently to clear the standard pintle hole, so fuel must be discharged through the auxiliary hole. Fuel passing through the auxiliary hole is directed at the hot center of the combustion chamber where the chances of ignition are highest. At normal running speeds, when pressure in the fuel system is higher, the main nozzle valve unseats from the main pintle hole to allow the bulk of fuel to be discharged from it. Under normal operating conditions, no more than 15% of the total fuel volume should pass through the aux- iliary hole. This is because the smaller diameter auxiliary pintle hole is prone to blockage from solids in the fuel stream and carbon deposits. Pintle Figure 18-6. The shape of the pintle nozzle pin affects the shape of the spray cone produced. Throttling pintle nozzle (pilot injection) Closed Slightly open (initial spray) Fully open (main spray) A B C Figure 18-7. Throttling pintle nozzle operation. Auxilliary spray hole Figure 18-8. CAV Pentaux® nozzle with auxiliary spray hole.