24 GD&T: Application and Interpretation

Copyright Goodheart-Willcox Co., Inc.

Introduction

Symbology is used to express dimensioning

and tolerancing requirements in engineering doc-

umentation, which includes engineering drawings

and computer-aided design (CAD) models. The

shapes of dimensioning and tolerancing symbols

provide a logical connection between the sym-

bol and the characteristic it represents. The easily

identifi able shapes of the symbols permit a stan-

dard symbol set to be used internationally without

the problems caused by differences in language.

It is important to create engineering drawings

that have clearly defi ned dimensional require-

ments. The symbology defi ned by ASME Y14.5

makes a clear and consistent expression of require-

ments possible. The same level of clarity and con-

sistency is diffi cult to achieve when notes are used

instead of symbols. The diffi culty with notations is

caused by differences in language mastery levels

and personal writing styles.

All tolerances are applied to part features, and

part features fall into two major categories. They

are either surfaces or features of size. As the mean-

ings of tolerancing symbols are explained, some of

them are limited to application on one of the two

feature types. As an example, position tolerances

may only be applied to features of size. Another

example is the symbol for profi le of a surface, and

it may only be applied to surfaces. The meaning of

a couple of tolerance symbols is altered depending

on whether the symbol is applied to a surface or a

feature of size.

There are two classes for features of size. Reg-

ular features of size are typically associated with

a single size dimension such as thickness, width,

length, or diameter. Regular features of size are

made of common geometric shapes with a single

size dimension such as a cylinder, circle, or slot.

Irregular features of size may be one enclosed

shape or a collection of features that in combina-

tion establish a size boundary. A hexagonal shape

may be toleranced in such a manner that it is

treated as an irregular feature of size. Throughout

this text, the term feature of size is general and is

applied to both regular and irregular features of

size.

General Symbols and

Abbreviations

Some dimension values shown on a drawing

require clarifi cation through the use of symbols.

As an example, a dimension applied to specify

the diameter of a circular feature, such as a hole,

includes a diameter symbol. The diameter symbol

makes it clear that the specifi ed value is a diam-

eter, and not a radius or spherical diameter.

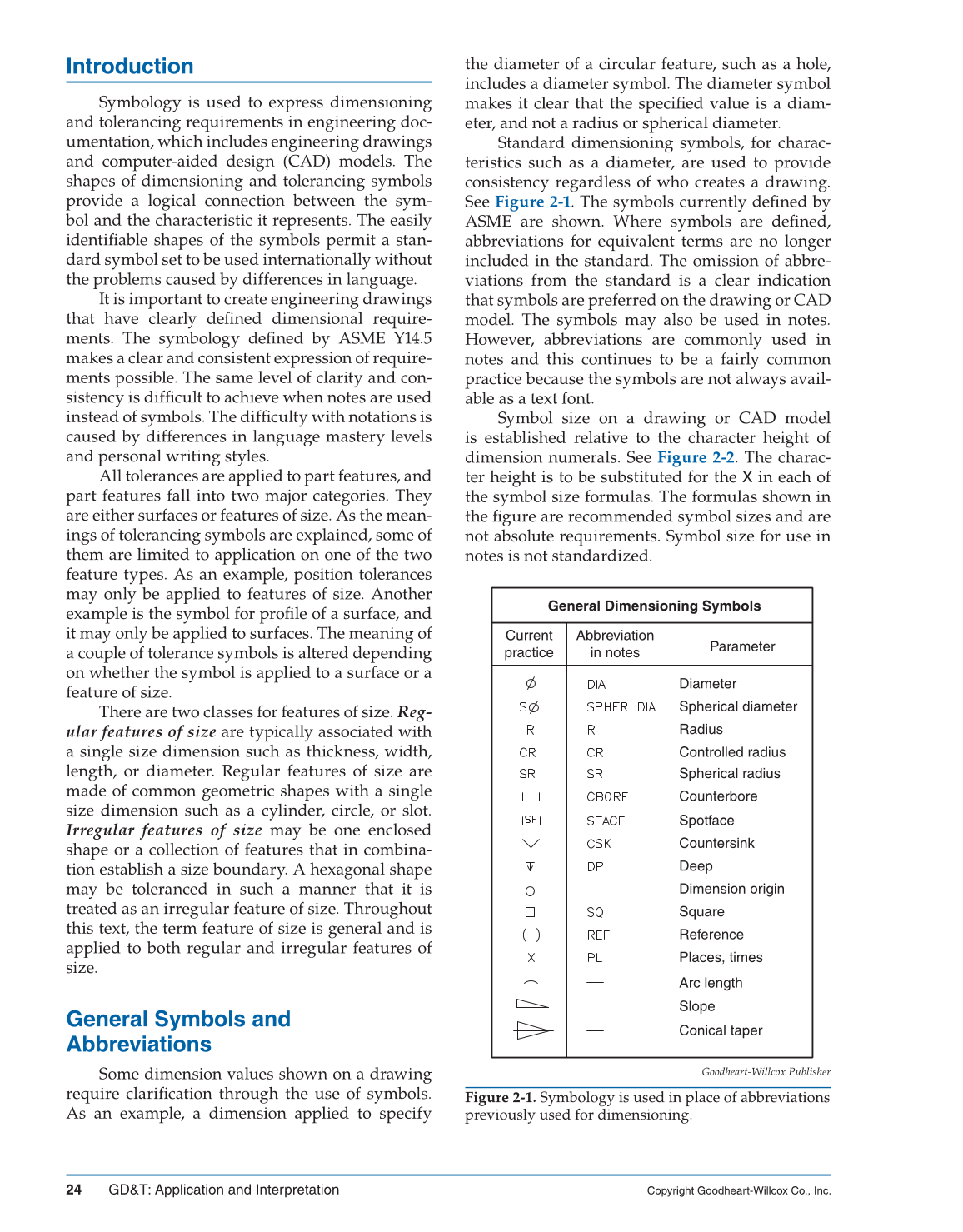

Standard dimensioning symbols, for charac-

teristics such as a diameter, are used to provide

consistency regardless of who creates a drawing.

See Figure 2-1. The symbols currently defi ned by

ASME are shown. Where symbols are defi ned,

abbreviations for equivalent terms are no longer

included in the standard. The omission of abbre-

viations from the standard is a clear indication

that symbols are preferred on the drawing or CAD

model. The symbols may also be used in notes.

However, abbreviations are commonly used in

notes and this continues to be a fairly common

practice because the symbols are not always avail-

able as a text font.

Symbol size on a drawing or CAD model

is established relative to the character height of

dimension numerals. See Figure 2-2. The charac-

ter height is to be substituted for the X in each of

the symbol size formulas. The formulas shown in

the fi gure are recommended symbol sizes and are

not absolute requirements. Symbol size for use in

notes is not standardized.

Parameter

Diameter

Spherical diameter

Radius

Spherical radius

Counterbore

Spotface

Countersink

Deep

Dimension origin

Square

Reference

Places, times

Arc length

Slope

Conical taper

General Dimensioning Symbols

Controlled radius

Current

practice

Abbreviation

in notes

Goodheart-Willcox Publisher

Figure 2-1. Symbology is used in place of abbreviations

previously used for dimensioning.