Chapter 21 Substrates 385

The mechanical pulpmaking process (groundwood

process) uses grinding wheels to reduce the logs to

fi ber. The by-product is pulp with high opacity but

relatively low strength.

Sizing and Fillers

Sizing is added to the pulp slurry to make the

paper more resistant to moisture. Rosin is a common

sizing material. Alum is added as a binding agent.

Binding is a part of the sizing process.

Fillers are needed to improve a paper’s opacity,

brightness, smoothness, and ink receptivity. Two

common fi llers are clay and titanium dioxide.

Dyes, Pigments, and Bleach

Dyes and pigments are added to produce colored

substrates, while bleach makes the pulp white. Coloring

or bleaching additives are mixed in vats called pulpers.

The pulp goes through a fi nal beating and refi ning stage

before it is pumped to a stock chest.

Removing Water

A jordan machine is a beater or refi ner of the

fi bers. A jordan machine refi nes the fi ber slurry

until it is about 99% water and 1% fi ber and other

solids. At this point, the paper is known as furnish.

The solution is pumped into the headbox of the

papermaking machine.

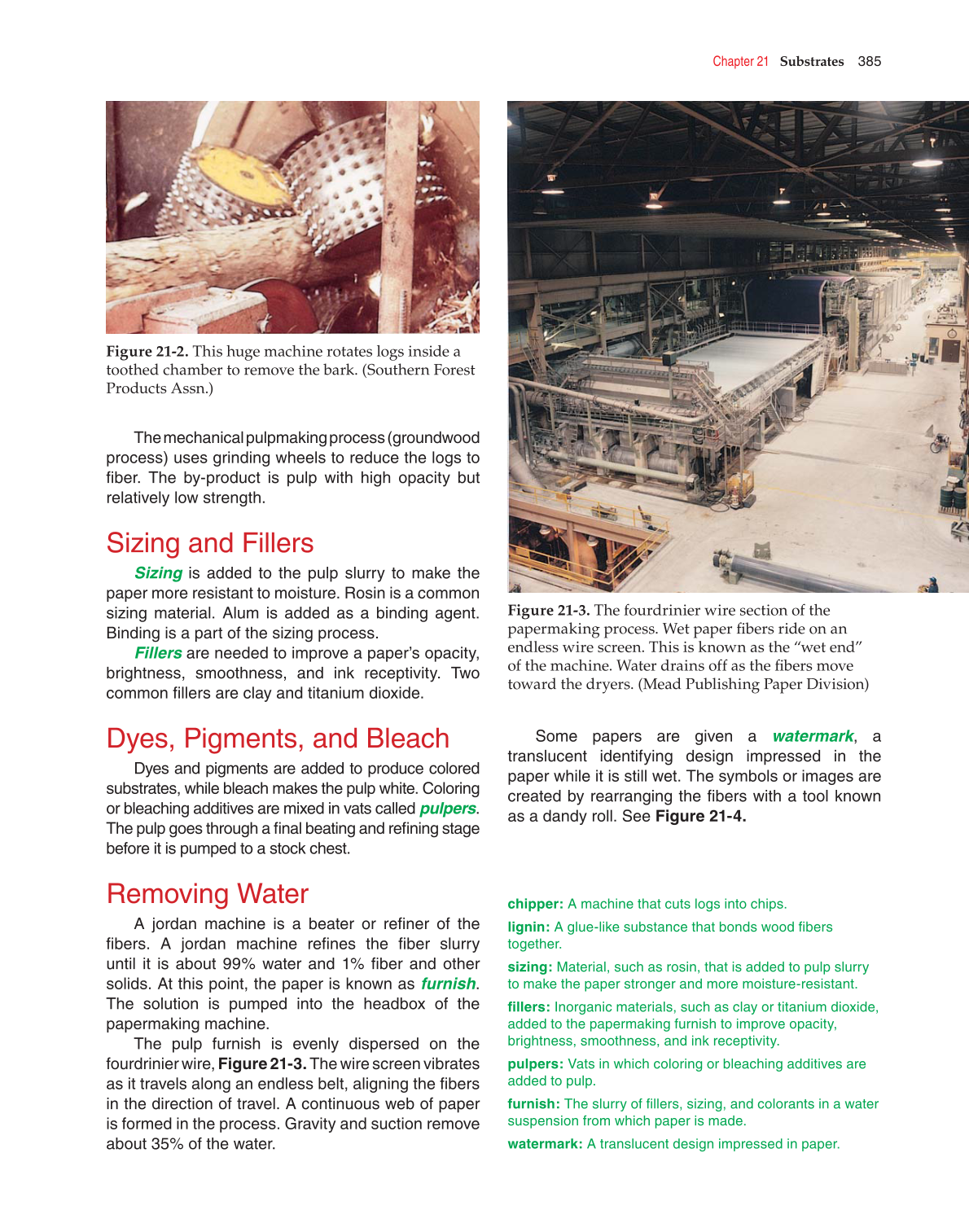

The pulp furnish is evenly dispersed on the

fourdrinier wire, Figure 21-3. The wire screen vibrates

as it travels along an endless belt, aligning the fi bers

in the direction of travel. A continuous web of paper

is formed in the process. Gravity and suction remove

about 35% of the water.

Some papers are given a watermark, a

translucent identifying design impressed in the

paper while it is still wet. The symbols or images are

created by rearranging the fi bers with a tool known

as a dandy roll. See Figure 21-4.

Figure 21-2. This huge machine rotates logs inside a

toothed chamber to remove the bark. (Southern Forest

Products Assn.)

Figure 21-3. The fourdrinier wire section of the

papermaking process. Wet paper fi bers ride on an

endless wire screen. This is known as the “wet end”

of the machine. Water drains off as the fi bers move

toward the dryers. (Mead Publishing Paper Division)

chipper: A machine that cuts logs into chips.

lignin: A glue-like substance that bonds wood fi bers

together.

sizing: Material, such as rosin, that is added to pulp slurry

to make the paper stronger and more moisture-resistant.

fi llers: Inorganic materials, such as clay or titanium dioxide,

added to the papermaking furnish to improve opacity,

brightness, smoothness, and ink receptivity.

pulpers: Vats in which coloring or bleaching additives are

added to pulp.

furnish: The slurry of fi llers, sizing, and colorants in a water

suspension from which paper is made.

watermark: A translucent design impressed in paper.