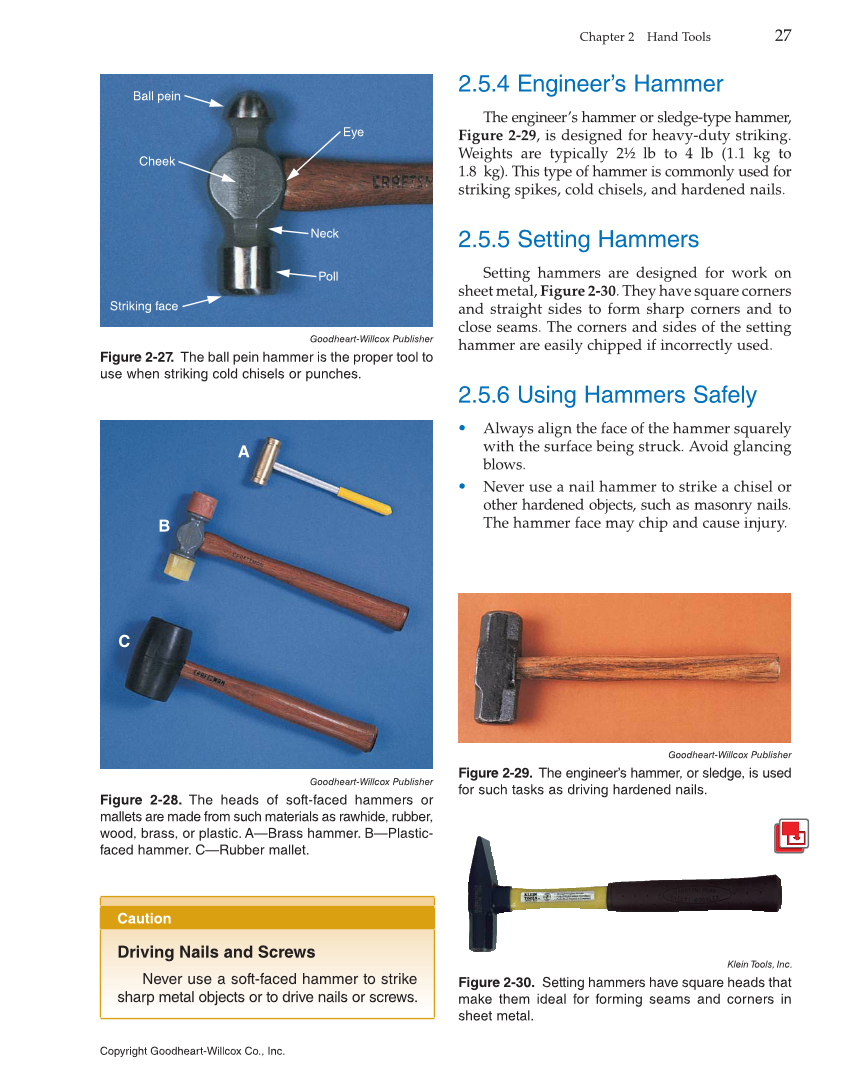

2.5.4 Engineer’s Hammer The engineer’s hammer or sledge-type hammer, Figure 2-29, is designed for heavy-duty striking. Weights are typically 2½ lb to 4 lb (1.1 kg to 1.8 kg). This type of hammer is commonly used for striking spikes, cold chisels, and hardened nails. 2.5.5 Setting Hammers Setting hammers are designed for work on sheet metal, Figure 2-30. They have square corners and straight sides to form sharp corners and to close seams. The corners and sides of the setting hammer are easily chipped if incorrectly used. 2.5.6 Using Hammers Safely • Always align the face of the hammer squarely with the surface being struck. Avoid glancing blows. • Never use a nail hammer to strike a chisel or other hardened objects, such as masonry nails. The hammer face may chip and cause injury. Caution Driving Nails and Screws Never use a soft-faced hammer to strike sharp metal objects or to drive nails or screws. Ball pein Cheek Eye Poll Striking face Neck Goodheart-Willcox Publisher Figure 2-27. The ball pein hammer is the proper tool to use when striking cold chisels or punches. A B C Goodheart-Willcox Publisher Figure 2-28. The heads of soft-faced hammers or mallets are made from such materials as rawhide, rubber, wood, brass, or plastic. A—Brass hammer. B—Plastic- faced hammer. C—Rubber mallet. Goodheart-Willcox Publisher Figure 2-29. The engineer’s hammer, or sledge, is used for such tasks as driving hardened nails. Klein Tools, Inc. Figure 2-30. Setting hammers have square heads that make them ideal for forming seams and corners in sheet metal. Chapter 2 Hand Tools 27 Copyright Goodheart-Willcox Co., Inc.