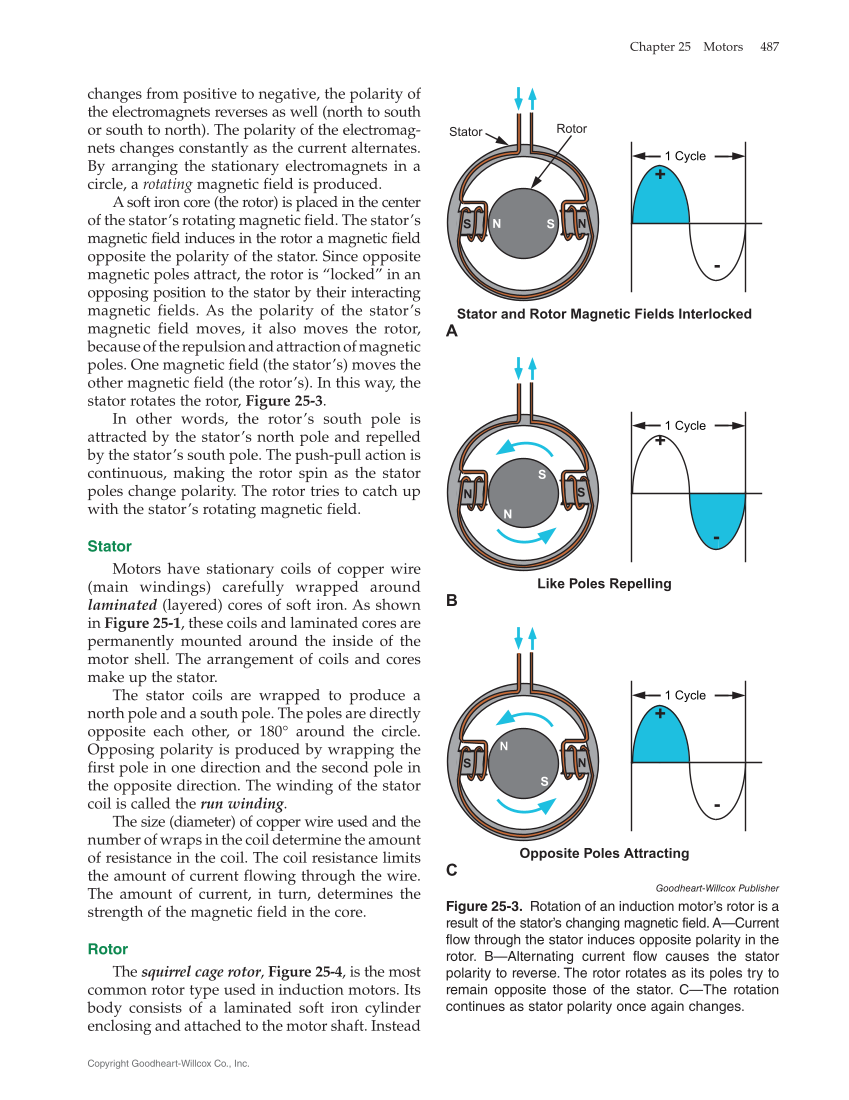

changes from positive to negative, the polarity of the electromagnets reverses as well (north to south or south to north). The polarity of the electromag- nets changes constantly as the current alternates. By arranging the stationary electromagnets in a circle, a rotating magnetic field is produced. A soft iron core (the rotor) is placed in the center of the stator’s rotating magnetic field. The stator’s magnetic field induces in the rotor a magnetic field opposite the polarity of the stator. Since opposite magnetic poles attract, the rotor is “locked” in an opposing position to the stator by their interacting magnetic fields. As the polarity of the stator’s magnetic field moves, it also moves the rotor, because of the repulsion and attraction of magnetic poles. One magnetic field (the stator’s) moves the other magnetic field (the rotor’s). In this way, the stator rotates the rotor, Figure 25‑3. In other words, the rotor’s south pole is attracted by the stator’s north pole and repelled by the stator’s south pole. The push-pull action is continuous, making the rotor spin as the stator poles change polarity. The rotor tries to catch up with the stator’s rotating magnetic field. Stator Motors have stationary coils of copper wire (main windings) carefully wrapped around laminated (layered) cores of soft iron. As shown in Figure 25‑1, these coils and laminated cores are permanently mounted around the inside of the motor shell. The arrangement of coils and cores make up the stator. The stator coils are wrapped to produce a north pole and a south pole. The poles are directly opposite each other, or 180° around the circle. Opposing polarity is produced by wrapping the first pole in one direction and the second pole in the opposite direction. The winding of the stator coil is called the run winding. The size (diameter) of copper wire used and the number of wraps in the coil determine the amount of resistance in the coil. The coil resistance limits the amount of current flowing through the wire. The amount of current, in turn, determines the strength of the magnetic field in the core. Rotor The squirrel cage rotor, Figure 25‑4, is the most common rotor type used in induction motors. Its body consists of a laminated soft iron cylinder enclosing and attached to the motor shaft. Instead Stator and Rotor Magnetic Fields Interlocked A Like Poles Repelling B Opposite Poles Attracting C 1 Cycle + - 1 Cycle - + 1 Cycle + - N S S N Rotor Stator N S S N N S S N N Goodheart-Willcox Publisher Figure 25‑3. Rotation of an induction motor’s rotor is a result of the stator’s changing magnetic field. A—Current flow through the stator induces opposite polarity in the rotor. B—Alternating current flow causes the stator polarity to reverse. The rotor rotates as its poles try to remain opposite those of the stator. C—The rotation continues as stator polarity once again changes. Chapter 25 Motors 487 Copyright Goodheart-Willcox Co., Inc.