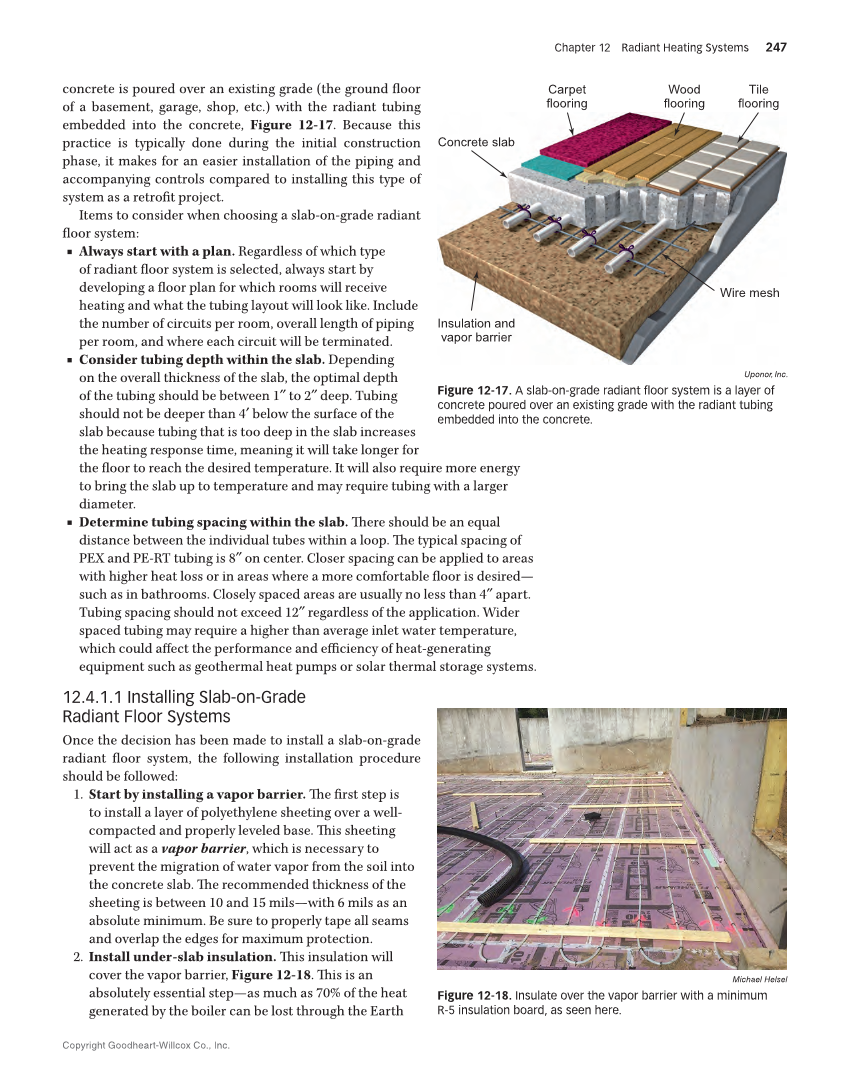

Copyright Goodheart-Willcox Co., Inc. Chapter 12 Radiant Heating Systems 247 concrete is poured over an existing grade (the ground floor of a basement, garage, shop, etc.) with the radiant tubing embedded into the concrete, Figure 12-17. Because this practice is typically done during the initial construction phase, it makes for an easier installation of the piping and accompanying controls compared to installing this type of system as a retrofit project. Items to consider when choosing a slab-on-grade radiant floor system: ■ ■ Always start with a plan. Regardless of which type of radiant floor system is selected, always start by developing a floor plan for which rooms will receive heating and what the tubing layout will look like. Include the number of circuits per room, overall length of piping per room, and where each circuit will be terminated. ■ ■ Consider tubing depth within the slab. Depending on the overall thickness of the slab, the optimal depth of the tubing should be between 1″ to 2″ deep. Tubing should not be deeper than 4′ below the surface of the slab because tubing that is too deep in the slab increases the heating response time, meaning it will take longer for the floor to reach the desired temperature. It will also require more energy to bring the slab up to temperature and may require tubing with a larger diameter. ■ ■ Determine tubing spacing within the slab. There should be an equal distance between the individual tubes within a loop. The typical spacing of PEX and PE-RT tubing is 8″ on center. Closer spacing can be applied to areas with higher heat loss or in areas where a more comfortable floor is desired— such as in bathrooms. Closely spaced areas are usually no less than 4″ apart. Tubing spacing should not exceed 12″ regardless of the application. Wider spaced tubing may require a higher than average inlet water temperature, which could affect the performance and efficiency of heat-generating equipment such as geothermal heat pumps or solar thermal storage systems. 12.4.1.1 Installing Slab-on-Grade Radiant Floor Systems Once the decision has been made to install a slab-on-grade radiant floor system, the following installation procedure should be followed: 1. Start by installing a vapor barrier. The first step is to install a layer of polyethylene sheeting over a well- compacted and properly leveled base. This sheeting will act as a vapor barrier, which is necessary to prevent the migration of water vapor from the soil into the concrete slab. The recommended thickness of the sheeting is between 10 and 15 mils—with 6 mils as an absolute minimum. Be sure to properly tape all seams and overlap the edges for maximum protection. 2. Install under-slab insulation. This insulation will cover the vapor barrier, Figure 12-18. This is an absolutely essential step—as much as 70% of the heat generated by the boiler can be lost through the Earth Insulation and vapor barrier Concrete slab Carpet flooring Wood flooring Tile flooring Wire mesh Uponor, Inc. Figure 12-17. A slab-on-grade radiant floor system is a layer of concrete poured over an existing grade with the radiant tubing embedded into the concrete. Michael Helsel Figure 12-18. Insulate over the vapor barrier with a minimum R-5 insulation board, as seen here.