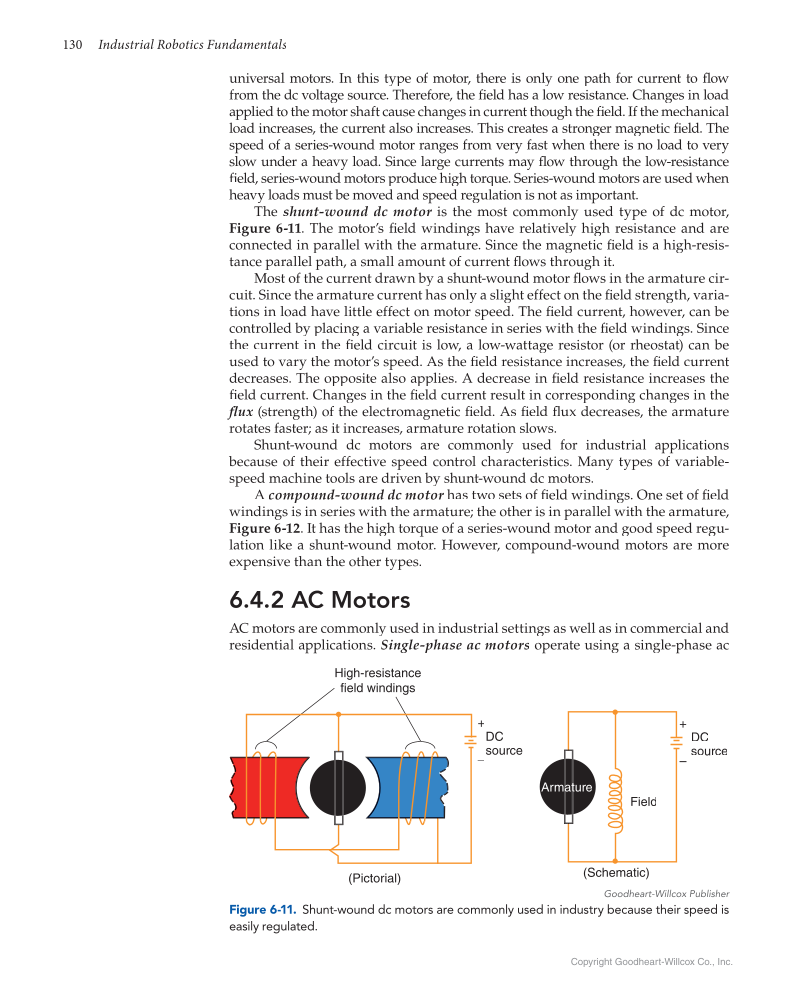

130 Industrial Robotics Fundamentals Copyright Goodheart-Willcox Co., Inc. universal motors. In this type of motor, there is only one path for current to flow fl from the dc voltage source. Therefore, the fi eld has a low resistance. Changes in load fi applied to the motor shaft cause changes in current though the field. If the mechanical fi load increases, the current also increases. This creates a stronger magnetic field. The fi speed of a series-wound motor ranges from very fast when there is no load to very slow under a heavy load. Since large currents may fl ow through the low-resistance fl fi eld, series-wound motors produce high torque. Series-wound motors are used when fi heavy loads must be moved and speed regulation is not as important. The shunt-wound dc motor is the most commonly used type of dc motor, r Figure 6-11. The motor’s fi eld windings have relatively high resistance and are fi connected in parallel with the armature. Since the magnetic fi eld is a high-resis- fi tance parallel path, a small amount of current fl ows through it. fl Most of the current drawn by a shunt-wound motor flows in the armature cir- fl cuit. Since the armature current has only a slight effect on the fi eld strength, varia- fi tions in load have little effect on motor speed. The field current, however, can be fi controlled by placing a variable resistance in series with the fi eld windings. Since fi the current in the fi eld circuit is low, a low-wattage resistor (or rheostat) can be fi used to vary the motor’s speed. As the field resistance increases, the field fi current fi decreases. The opposite also applies. A decrease in field resistance increases the fi fi eld current. Changes in the field fi current result in corresponding changes in the fi flux fl (strength) of the electromagnetic field. As field fi flux fi decreases, the armature fl rotates faster as it increases, armature rotation slows. Shunt-wound dc motors are commonly used for industrial applications because of their effective speed control characteristics. Many types of variable- speed machine tools are driven by shunt-wound dc motors. A compound-wound dc motor has two sets of field r windings. One set of field fi fi windings is in series with the armature the other is in parallel with the armature, Figure 6-12. It has the high torque of a series-wound motor and good speed regu- lation like a shunt-wound motor. However, compound-wound motors are more expensive than the other types. 6.4.2 AC Motors AC motors are commonly used in industrial settings as well as in commercial and residential applications. Single-phase ac motors operate using a single-phase ac + – (Pictorial) + – DC source (Schematic) Field Armature High-resistance field windings DC source Goodheart-Willcox Publisher Figure 6-11. Shunt-wound dc motors are commonly used in industry because their speed is easily regulated.