Copyright by Goodheart-Willcox Co., Inc.

304 Manual Drive Trains and Axles

Install recommended

type and amount

of grease

Lock boot clamp

securely with a

suitable tool

Bend over

to lock

Boot clamp

A

B

Check boot length between

boot clamps A and B

(A) (B)

Tape measure

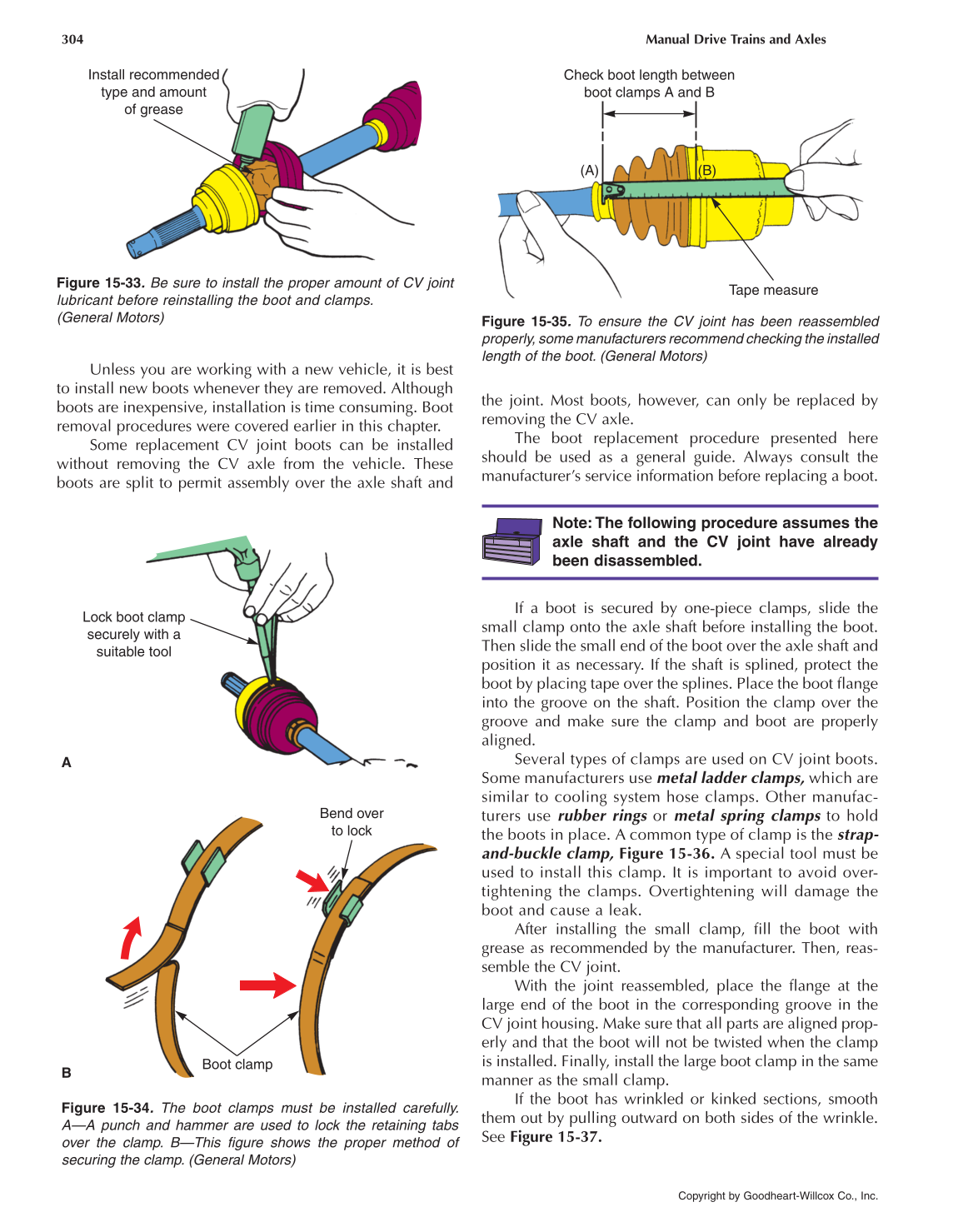

Figure 15-34. The boot clamps must be installed carefully.

A—A punch and hammer are used to lock the retaining tabs

over the clamp. B—This figure shows the proper method of

securing the clamp. (General Motors)

Figure 15-35. To ensure the CV joint has been reassembled

properly, some manufacturers recommend checking the installed

length of the boot. (General Motors)

Figure 15-33. Be sure to install the proper amount of CV joint

lubricant before reinstalling the boot and clamps.

(General Motors)

Unless you are working with a new vehicle, it is best

to install new boots whenever they are removed. Although

boots are inexpensive, installation is time consuming. Boot

removal procedures were covered earlier in this chapter.

Some replacement CV joint boots can be installed

without removing the CV axle from the vehicle. These

boots are split to permit assembly over the axle shaft and

the joint. Most boots, however, can only be replaced by

removing the CV axle.

The boot replacement procedure presented here

should be used as a general guide. Always consult the

manufacturer’s service information before replacing a boot.

Note: The following procedure assumes the

axle shaft and the CV joint have already

been disassembled.

If a boot is secured by one-piece clamps, slide the

small clamp onto the axle shaft before installing the boot.

Then slide the small end of the boot over the axle shaft and

position it as necessary. If the shaft is splined, protect the

boot by placing tape over the splines. Place the boot flange

into the groove on the shaft. Position the clamp over the

groove and make sure the clamp and boot are properly

aligned.

Several types of clamps are used on CV joint boots.

Some manufacturers use metal ladder clamps, which are

similar to cooling system hose clamps. Other manufac-

turers use rubber rings or metal spring clamps to hold

the boots in place. A common type of clamp is the strap-

and-buckle clamp, Figure 15-36. A special tool must be

used to install this clamp. It is important to avoid over-

tightening the clamps. Overtightening will damage the

boot and cause a leak.

After installing the small clamp, fill the boot with

grease as recommended by the manufacturer. Then, reas-

semble the CV joint.

With the joint reassembled, place the flange at the

large end of the boot in the corresponding groove in the

CV joint housing. Make sure that all parts are aligned prop-

erly and that the boot will not be twisted when the clamp

is installed. Finally, install the large boot clamp in the same

manner as the small clamp.

If the boot has wrinkled or kinked sections, smooth

them out by pulling outward on both sides of the wrinkle.

See Figure 15-37.