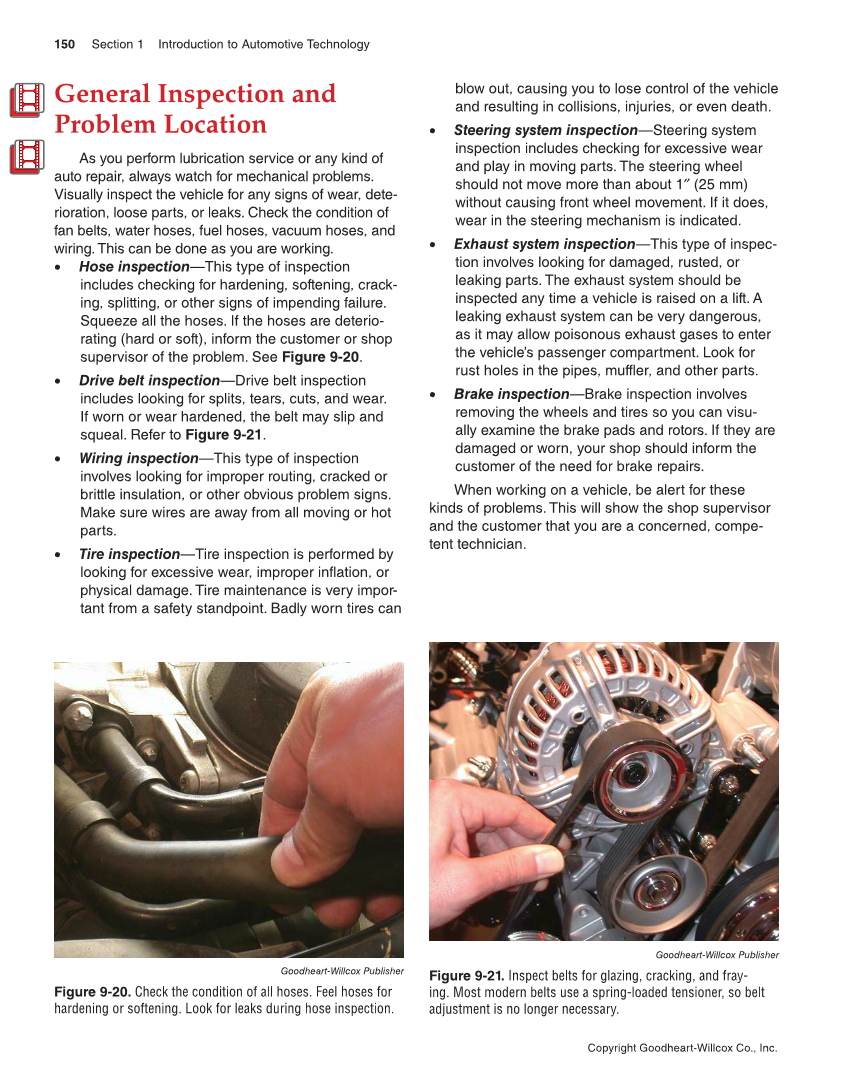

150 Section 1 Introduction to Automotive Technology Copyright Goodheart-Willcox Co., Inc. General Inspection and Problem Location As you perform lubrication service or any kind of auto repair, always watch for mechanical problems. Visually inspect the vehicle for any signs of wear, dete- rioration, loose parts, or leaks. Check the condition of fan belts, water hoses, fuel hoses, vacuum hoses, and wiring. This can be done as you are working. „ Hose inspection—This type of inspection includes checking for hardening, softening, crack- ing, splitting, or other signs of impending failure. Squeeze all the hoses. If the hoses are deterio- rating (hard or soft), inform the customer or shop supervisor of the problem. See Figure 9-20. „ Drive belt inspection—Drive belt inspection includes looking for splits, tears, cuts, and wear. If worn or wear hardened, the belt may slip and squeal. Refer to Figure 9-21. „ Wiring inspection—This type of inspection involves looking for improper routing, cracked or brittle insulation, or other obvious problem signs. Make sure wires are away from all moving or hot parts. „ Tire inspection—Tire inspection is performed by looking for excessive wear, improper inflation, or physical damage. Tire maintenance is very impor- tant from a safety standpoint. Badly worn tires can blow out, causing you to lose control of the vehicle and resulting in collisions, injuries, or even death. „ Steering system inspection—Steering system inspection includes checking for excessive wear and play in moving parts. The steering wheel should not move more than about 1″ (25 mm) without causing front wheel movement. If it does, wear in the steering mechanism is indicated. „ Exhaust system inspection—This type of inspec- tion involves looking for damaged, rusted, or leaking parts. The exhaust system should be inspected any time a vehicle is raised on a lift. A leaking exhaust system can be very dangerous, as it may allow poisonous exhaust gases to enter the vehicle’s passenger compartment. Look for rust holes in the pipes, muffler, and other parts. „ Brake inspection—Brake inspection involves removing the wheels and tires so you can visu- ally examine the brake pads and rotors. If they are damaged or worn, your shop should inform the customer of the need for brake repairs. When working on a vehicle, be alert for these kinds of problems. This will show the shop supervisor and the customer that you are a concerned, compe- tent technician. Goodheart-Willcox Publisher Figure 9-20. Check the condition of all hoses. Feel hoses for hardening or softening. Look for leaks during hose inspection. Goodheart-Willcox Publisher Figure 9-21. Inspect belts for glazing, cracking, and fray- ing. Most modern belts use a spring-loaded tensioner, so belt adjustment is no longer necessary.