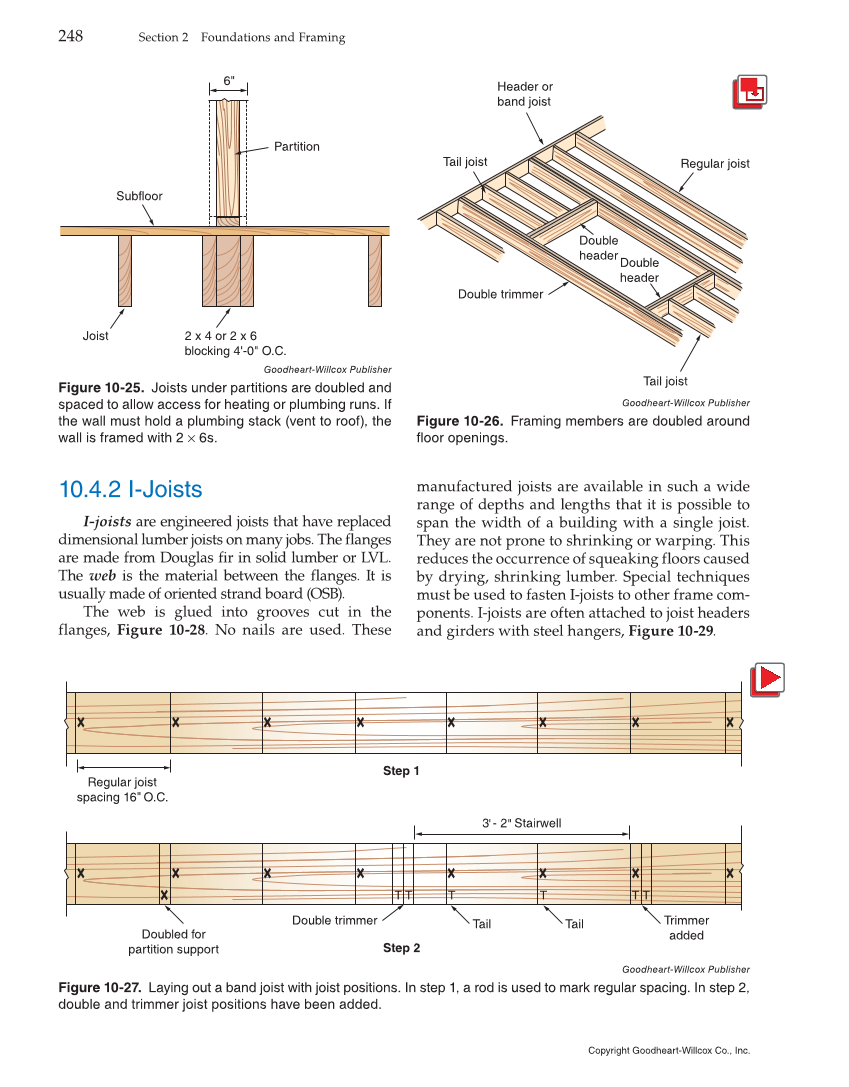

248 Section 2 Foundations and Framing 10.4.2 I-Joists I-joists are engineered joists that have replaced dimensional lumber joists on many jobs. The flanges are made from Douglas fir in solid lumber or LVL. The web is the material between the flanges. It is usually made of oriented strand board (OSB). The web is glued into grooves cut in the flanges, Figure 10-28. No nails are used. These manufactured joists are available in such a wide range of depths and lengths that it is possible to span the width of a building with a single joist. They are not prone to shrinking or warping. This reduces the occurrence of squeaking floors caused by drying, shrinking lumber. Special techniques must be used to fasten I-joists to other frame com- ponents. I-joists are often attached to joist headers and girders with steel hangers, Figure 10-29. 6" Partition Subfloor 2 x 4 or 2 x 6 blocking 4'-0" O.C. Joist Goodheart-Willcox Publisher Figure 10-25. Joists under partitions are doubled and spaced to allow access for heating or plumbing runs. If the wall must hold a plumbing stack (vent to roof), the wall is framed with 2 × 6s. Header or band joist Tail joist Regular joist Tail joist Double trimmer Double header Double header Goodheart-Willcox Publisher Figure 10-26. Framing members are doubled around floor openings. Step 1 Regular joist spacing 16 O.C. 3 - 2 Stairwell Step 2 Doubled for partition support Double trimmer Trimmer added Tail Tail T T T T T T Goodheart-Willcox Publisher Figure 10-27. Laying out a band joist with joist positions. In step 1, a rod is used to mark regular spacing. In step 2, double and trimmer joist positions have been added. Copyright Goodheart-Willcox Co., Inc.