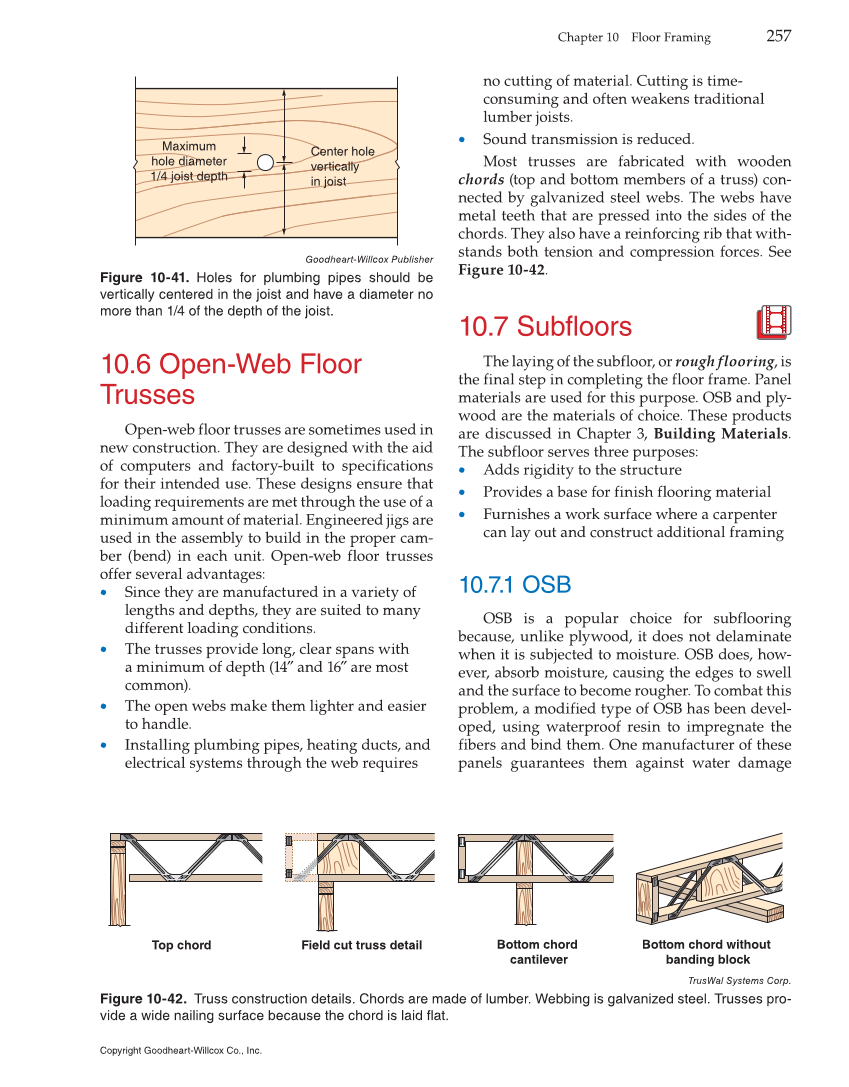

Chapter 10 Floor Framing 257 10.6 Open-Web Floor Trusses Open-web floor trusses are sometimes used in new construction. They are designed with the aid of computers and factory-built to specifications for their intended use. These designs ensure that loading requirements are met through the use of a minimum amount of material. Engineered jigs are used in the assembly to build in the proper cam- ber (bend) in each unit. Open-web floor trusses offer several advantages: • Since they are manufactured in a variety of lengths and depths, they are suited to many different loading conditions. • The trusses provide long, clear spans with a minimum of depth (14″ and 16″ are most common). • The open webs make them lighter and easier to handle. • Installing plumbing pipes, heating ducts, and electrical systems through the web requires no cutting of material. Cutting is time- consuming and often weakens traditional lumber joists. • Sound transmission is reduced. Most trusses are fabricated with wooden chords (top and bottom members of a truss) con- nected by galvanized steel webs. The webs have metal teeth that are pressed into the sides of the chords. They also have a reinforcing rib that with- stands both tension and compression forces. See Figure 10-42. 10.7 Subfloors The laying of the subfloor, or rough flooring, is the final step in completing the floor frame. Panel materials are used for this purpose. OSB and ply- wood are the materials of choice. These products are discussed in Chapter 3, Building Materials. The subfloor serves three purposes: • Adds rigidity to the structure • Provides a base for finish flooring material • Furnishes a work surface where a carpenter can lay out and construct additional framing 10.7.1 OSB OSB is a popular choice for subflooring because, unlike plywood, it does not delaminate when it is subjected to moisture. OSB does, how- ever, absorb moisture, causing the edges to swell and the surface to become rougher. To combat this problem, a modified type of OSB has been devel- oped, using waterproof resin to impregnate the fibers and bind them. One manufacturer of these panels guarantees them against water damage Center hole vertically in joist Maximum hole diameter 1/4 joist depth Goodheart-Willcox Publisher Figure 10-41. Holes for plumbing pipes should be vertically centered in the joist and have a diameter no more than 1/4 of the depth of the joist. Top chord Field cut truss detail Bottom chord cantilever Bottom chord without banding block TrusWal Systems Corp. Figure 10-42. Truss construction details. Chords are made of lumber. Webbing is galvanized steel. Trusses pro- vide a wide nailing surface because the chord is laid flat. Copyright Goodheart-Willcox Co., Inc.