472

Modern Refrigeration and Air Conditioning

Locating Compressor Faults

The most expensive service item for a domestic

refrigerator is the replacement of the compressor. The

technician should carefully check for all other electri-

cal and mechanical failures before determining that

the compressor needs replacement. When a compres-

sor is in good condition, the most common reason for

replacement is an electrical fault.

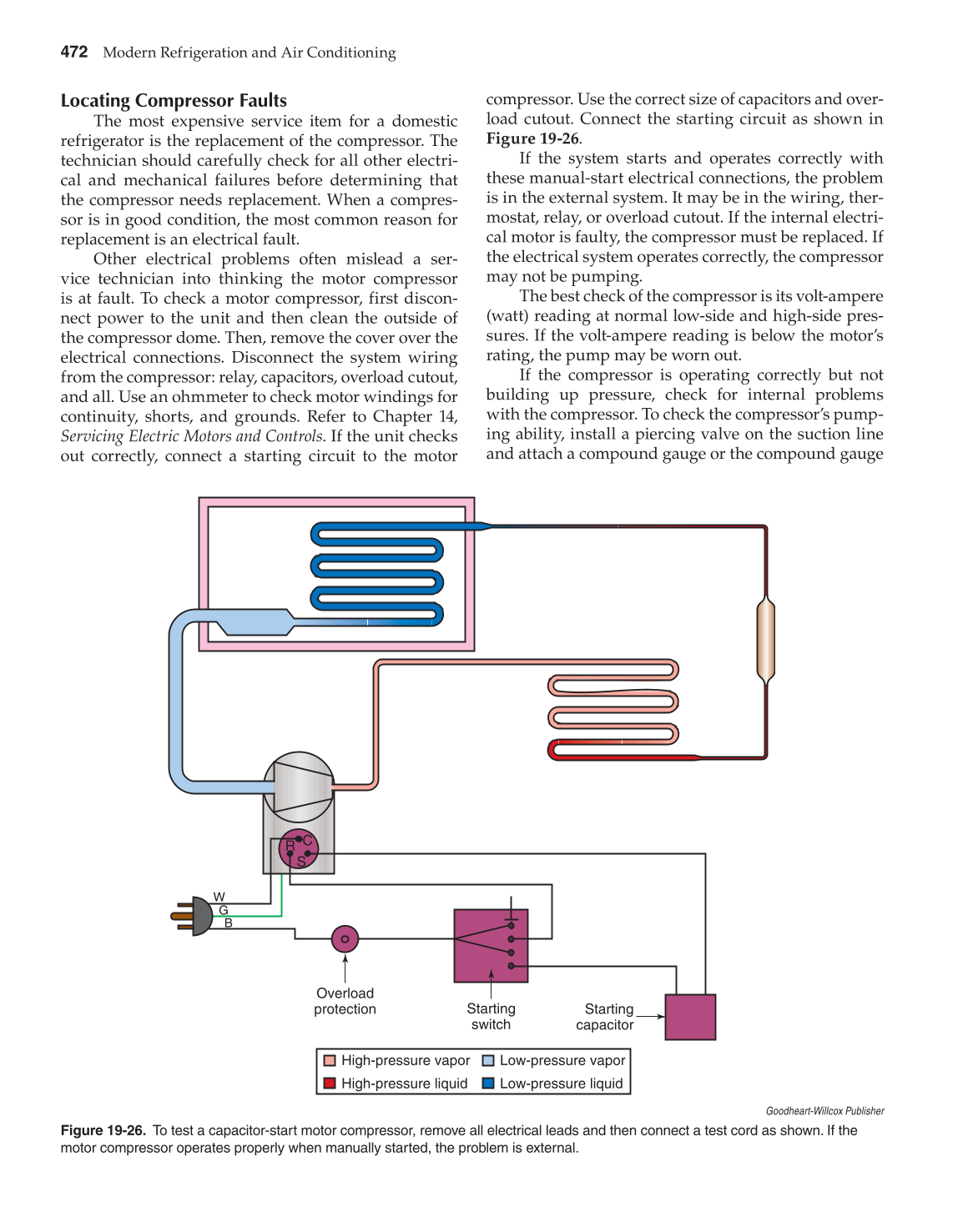

Other electrical problems often mislead a ser-

vice technician into thinking the motor compressor

is at fault. To check a motor compressor, first discon-

nect power to the unit and then clean the outside of

the compressor dome. Then, remove the cover over the

electrical connections. Disconnect the system wiring

from the compressor: relay, capacitors, overload cutout,

and all. Use an ohmmeter to check motor windings for

continuity, shorts, and grounds. Refer to Chapter 14,

Servicing Electric Motors and Controls. If the unit checks

out correctly, connect a starting circuit to the motor

compressor. Use the correct size of capacitors and over-

load cutout. Connect the starting circuit as shown in

Figure 19-26.

If the system starts and operates correctly with

these manual-start electrical connections, the problem

is in the external system. It may be in the wiring, ther-

mostat, relay, or overload cutout. If the internal electri-

cal motor is faulty, the compressor must be replaced. If

the electrical system operates correctly, the compressor

may not be pumping.

The best check of the compressor is its volt-ampere

(watt) reading at normal low-side and high-side pres-

sures. If the volt-ampere reading is below the motor’s

rating, the pump may be worn out.

If the compressor is operating correctly but not

building up pressure, check for internal problems

with the compressor. To check the compressor’s pump-

ing ability, install a piercing valve on the suction line

and attach a compound gauge or the compound gauge

Overload

protection

C

R

S

W

G

B

Starting

switch

Starting

capacitor

High-pressure vapor Low-pressure vapor

High-pressure liquid Low-pressure liquid

Goodheart-Willcox Publisher

Figure 19-26. To test a capacitor-start motor compressor, remove all electrical leads and then connect a test cord as shown. If the

motor compressor operates properly when manually started, the problem is external.