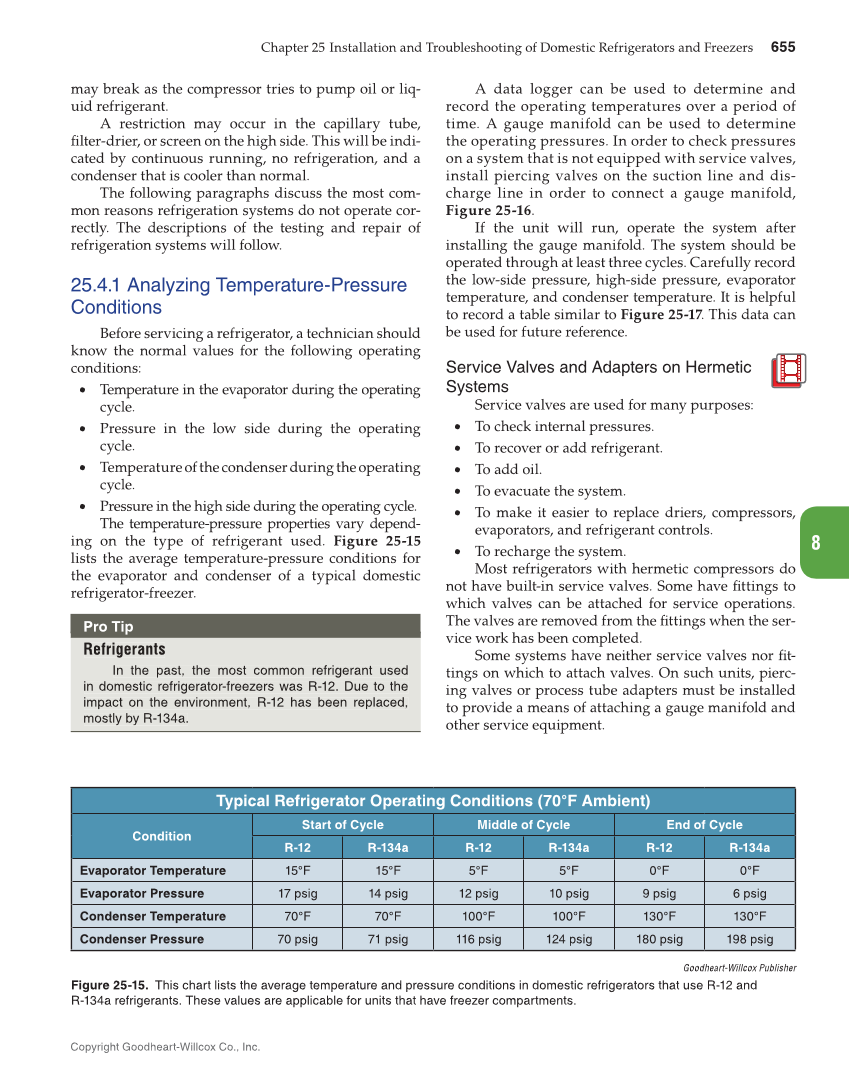

Chapter 25 Installation and Troubleshooting of Domestic Refrigerators and Freezers 655 Copyright Goodheart-Willcox Co., Inc. 8 may break as the compressor tries to pump oil or liq- uid refrigerant. A restriction may occur in the capillary tube, filter-drier, or screen on the high side. This will be indi- cated by continuous running, no refrigeration, and a condenser that is cooler than normal. The following paragraphs discuss the most com- mon reasons refrigeration systems do not operate cor- rectly. The descriptions of the testing and repair of refrigeration systems will follow. 25.4.1 Analyzing Temperature-Pressure Conditions Before servicing a refrigerator, a technician should know the normal values for the following operating conditions: • Temperature in the evaporator during the operating cycle. • Pressure in the low side during the operating cycle. • Temperature of the condenser during the operating cycle. • Pressure in the high side during the operating cycle. The temperature-pressure properties vary depend- ing on the type of refrigerant used. Figure 25-15 lists the average temperature-pressure conditions for the evaporator and condenser of a typical domestic refrigerator-freezer. Pro Tip Refrigerants In the past, the most common refrigerant used in domestic refrigerator-freezers was R-12. Due to the impact on the environment, R-12 has been replaced, mostly by R-134a. Refrigerant s In the past, the most common refrigerant used in domestic refrigerator-freezers was R-12. Due to the impact on t h e environment, R -12 h as b een replaced, mostl y b y R-134a . A data logger can be used to determine and record the operating temperatures over a period of time. A gauge manifold can be used to determine the operating pressures. In order to check pressures on a system that is not equipped with service valves, install piercing valves on the suction line and dis- charge line in order to connect a gauge manifold, Figure 25-16. If the unit will run, operate the system after installing the gauge manifold. The system should be operated through at least three cycles. Carefully record the low-side pressure, high-side pressure, evaporator temperature, and condenser temperature. It is helpful to record a table similar to Figure 25-17. This data can be used for future reference. Service Valves and Adapters on Hermetic Systems Service valves are used for many purposes: • To check internal pressures. • To recover or add refrigerant. • To add oil. • To evacuate the system. • To make it easier to replace driers, compressors, evaporators, and refrigerant controls. • To recharge the system. Most refrigerators with hermetic compressors do not have built-in service valves. Some have fittings to which valves can be attached for service operations. The valves are removed from the fittings when the ser- vice work has been completed. Some systems have neither service valves nor fit- tings on which to attach valves. On such units, pierc- ing valves or process tube adapters must be installed to provide a means of attaching a gauge manifold and other service equipment. Goodheart-Willcox Publisher Figure 25-15. This chart lists the average temperature and pressure conditions in domestic refrigerators that use R-12 and R-134a refrigerants. These values are applicable for units that have freezer compartments. Typical Refrigerator Operating Conditions (70°F Ambient) Condition Start of Cycle Middle of Cycle End of Cycle R-12 R-134a R-12 R-134a R-12 R-134a Evaporator Temperature 15°F 15°F 5°F 5°F 0°F 0°F Evaporator Pressure 17 psig 14 psig 12 psig 10 psig 9 psig 6 psig Condenser Temperature 70°F 70°F 100°F 100°F 130°F 130°F Condenser Pressure 70 psig 71 psig 116 psig 124 psig 180 psig 198 psig