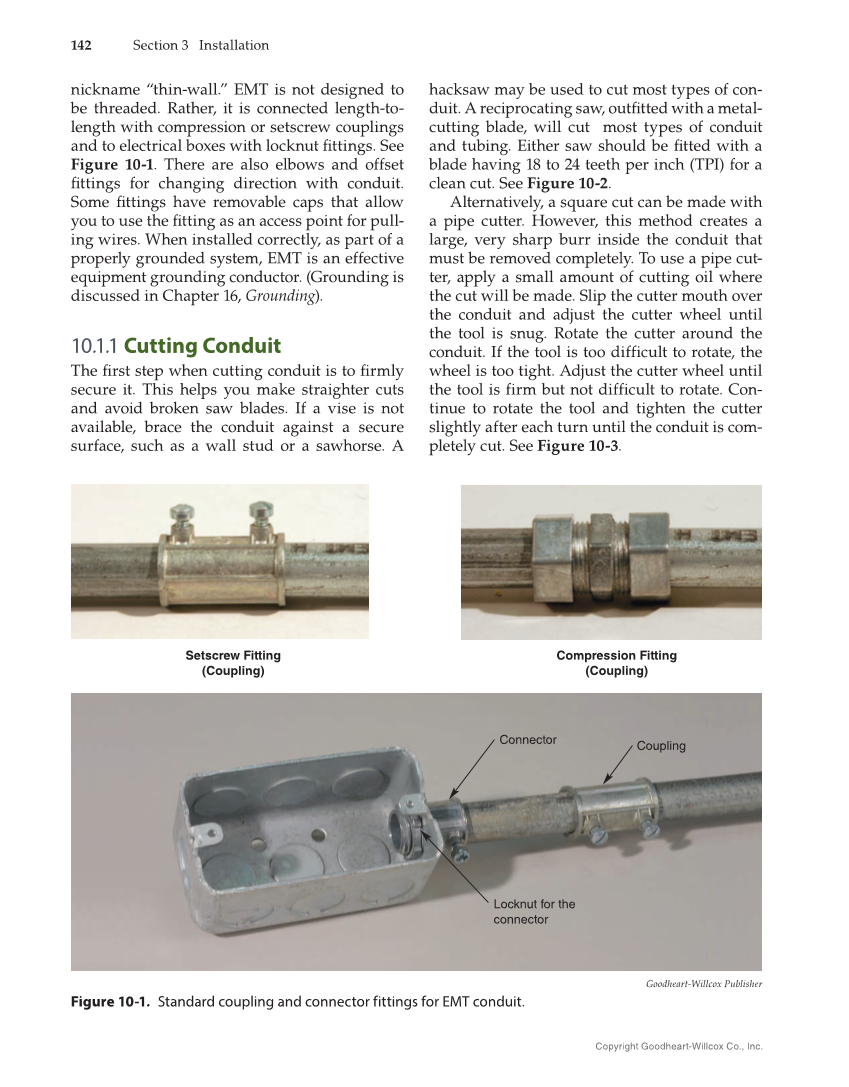

142 Section 3 Installation Copyright Goodheart-Willcox Co., Inc. nickname “thin-wall.” EMT is not designed to be threaded. Rather, it is connected length-to- length with compression or setscrew couplings and to electrical boxes with locknut fi ttings. See Figure 10-1. There are also elbows and offset fi ttings for changing direction with conduit. Some fi ttings have removable caps that allow you to use the fi tting as an access point for pull- ing wires. When installed correctly, as part of a properly grounded system, EMT is an effective equipment grounding conductor. (Grounding is discussed in Chapter 16, Grounding). 10.1.1 Cutting Conduit The fi rst step when cutting conduit is to fi rmly secure it. This helps you make straighter cuts and avoid broken saw blades. If a vise is not available, brace the conduit against a secure surface, such as a wall stud or a sawhorse. A hacksaw may be used to cut most types of con- duit. A reciprocating saw, outfi tted with a metal- cutting blade, will cut most types of conduit and tubing. Either saw should be fi tted with a blade having 18 to 24 teeth per inch (TPI) for a clean cut. See Figure 10-2. Alternatively, a square cut can be made with a pipe cutter. However, this method creates a large, very sharp burr inside the conduit that must be removed completely. To use a pipe cut- ter, apply a small amount of cutting oil where the cut will be made. Slip the cutter mouth over the conduit and adjust the cutter wheel until the tool is snug. Rotate the cutter around the conduit. If the tool is too difficult to rotate, the wheel is too tight. Adjust the cutter wheel until the tool is firm but not difficult to rotate. Con- tinue to rotate the tool and tighten the cutter slightly after each turn until the conduit is com- pletely cut. See Figure 10-3. Setscrew Fitting (Coupling) Compression Fitting (Coupling) Connector Coupling Locknut for the connector Goodheart-Willcox Publisher Figure 10-1. Standard coupling and connector fittings for EMT conduit.