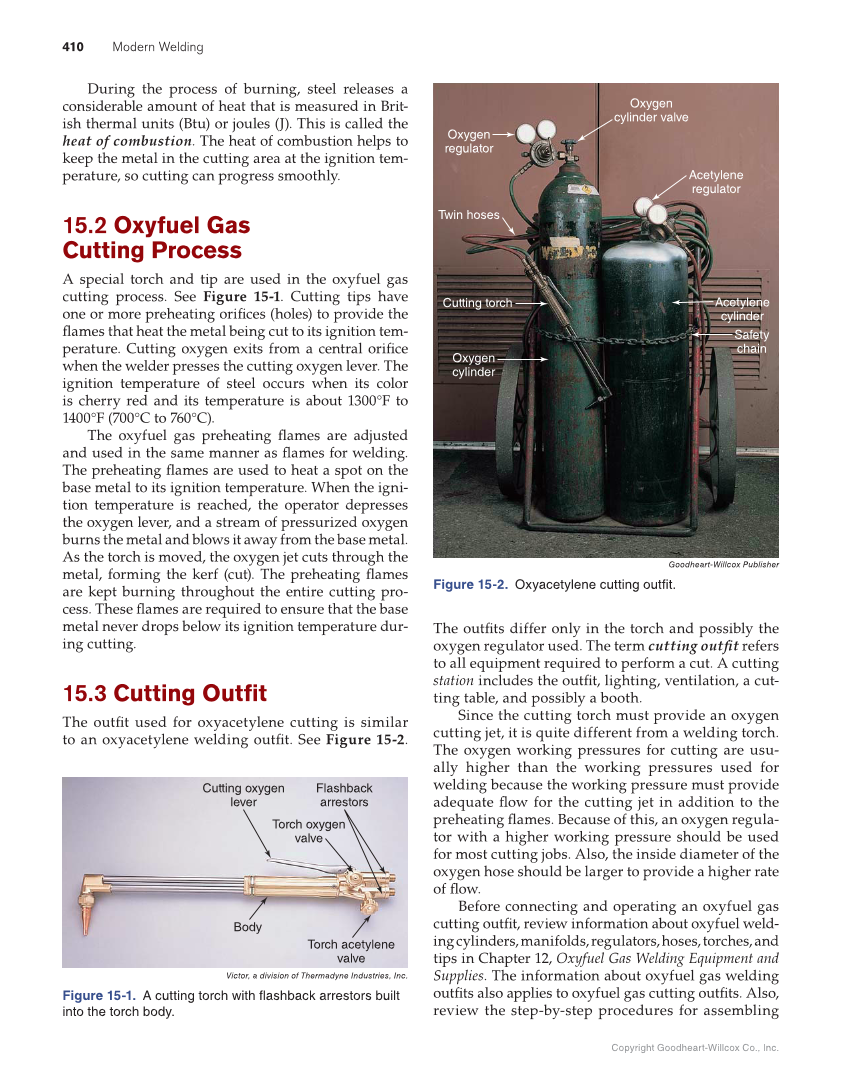

410 Modern Welding Copyright Goodheart-Willcox Co., Inc. During the process of burning, steel releases a considerable amount of heat that is measured in Brit- ish thermal units (Btu) or joules (J). This is called the heat of combustion. The heat of combustion helps to keep the metal in the cutting area at the ignition tem- perature, so cutting can progress smoothly. 15.2 Oxyfuel Gas Cutting Process A special torch and tip are used in the oxyfuel gas cutting process. See Figure 15-1. Cutting tips have one or more preheating orifi ces (holes) to provide the fl ames that heat the metal being cut to its ignition tem- perature. Cutting oxygen exits from a central orifi ce when the welder presses the cutting oxygen lever. The ignition temperature of steel occurs when its color is cherry red and its temperature is about 1300°F to 1400°F (700°C to 760°C). The oxyfuel gas preheating fl ames are adjusted and used in the same manner as fl ames for welding. The preheating fl ames are used to heat a spot on the base metal to its ignition temperature. When the igni- tion temperature is reached, the operator depresses the oxygen lever, and a stream of pressurized oxygen burns the metal and blows it away from the base metal. As the torch is moved, the oxygen jet cuts through the metal, forming the kerf (cut). The preheating fl ames are kept burning throughout the entire cutting pro- cess. These fl ames are required to ensure that the base metal never drops below its ignition temperature dur- ing cutting. 15.3 Cutting Outfit The outfi t used for oxyacetylene cutting is similar to an oxyacetylene welding outfi t. See Figure 15-2. The outfi ts differ only in the torch and possibly the oxygen regulator used. The term cutting outfi t refers to all equipment required to perform a cut. A cutting station includes the outfi t, lighting, ventilation, a cut- ting table, and possibly a booth. Since the cutting torch must provide an oxygen cutting jet, it is quite different from a welding torch. The oxygen working pressures for cutting are usu- ally higher than the working pressures used for welding because the working pressure must provide adequate fl ow for the cutting jet in addition to the preheating fl ames. Because of this, an oxygen regula- tor with a higher working pressure should be used for most cutting jobs. Also, the inside diameter of the oxygen hose should be larger to provide a higher rate of fl ow. Before connecting and operating an oxyfuel gas cutting outfi t, review information about oxyfuel weld- ing cylinders, manifolds, regulators, hoses, torches, and tips in Chapter 12, Oxyfuel Gas Welding Equipment and Supplies. The information about oxyfuel gas welding outfi ts also applies to oxyfuel gas cutting outfi ts. Also, review the step-by-step procedures for assembling Torch oxygen valve Cutting oxygen lever Body Torch acetylene valve Flashback arrestors Victor, a division of Thermadyne Industries, Inc. Figure 15-1. A cutting torch with flashback arrestors built into the torch body. Oxygen cylinder valve Acetylene regulator Acetylene cylinder Safety chain Oxygen regulator Twin hoses Cutting torch Oxygen cylinder Goodheart-Willcox Publisher Figure 15-2. Oxyacetylene cutting outfit.