778 Agricultural Mechanics and Technology Systems Copyright Goodheart-Willcox Co., Inc.

T

he shielded metal arc welding (SMAW) process, also known as stick

welding, involves using a consumable electrode, or metal rod, coated in a

fl ux to form the welded bead. Electricity from a welding machine creates

an electric arc between the electrode and the base metals. Welding current

is the fl ow of electricity that results in the welding arc. The amount of

heat generated by the arc is directly proportional to the amount of current

produced by the power source. When the welder establishes the arc, the

base metal and the electrode melt to form the weld pool, Figure 29-1. As

the molten pool cools, it resolidifi es to form a bonded joint. The fl ux coating

on the electrode chemically reacts to the heat of the arc, using up the oxygen

in the vicinity of the weld to create an oxygen-free shield of gas around the

molten pool. Residue from the fl ux forms a layer of slag that protects the

weld from atmospheric contamination as it cools. See Figure 29-2.

Development of

Electric Arc Welding

The art of blacksmithing was developed during the

Middle Ages. Blacksmiths, through forging processes,

formed and welded items of iron by hammering red-

hot pieces together until they bonded, Figure 29-3.

Developed near the close of the nineteenth century,

carbon arc welding (CAW) was the fi rst arc welding

process. In this process, an arc is created between a

copper-clad carbon electrode and the base metal. The

intense heat of the arc melts the surfaces of the base

metal to be joined. A separate fi ller rod, which carries

no electrical current, is often added to the weld, similar

to the way fi ller metal is added in the oxyacetylene

welding process.

The fi rst US patent for an arc welding

process using a metal electrode was awarded

in 1890 to C. L. Coffi n of Detroit, who used

an uncoated, electrically conductive wire

that melted to become part of the weld. The

fi rst coated metal electrodes, introduced in

about 1900, had a thin coating of clay or

lime, providing a more stable arc. During

the 1920s, electrode coatings were developed

that not only stabilized the arc but also

improved the physical characteristics of the

completed weld joint.

The shielded metal arc welding process

is best suited to bonding ferrous (iron-

containing) metals, including mild steel,

Goodheart-Willcox Publisher

Figure 29-1. Welders use electric energy from a

welding machine to form an electric arc between

the electrode and the base metal.

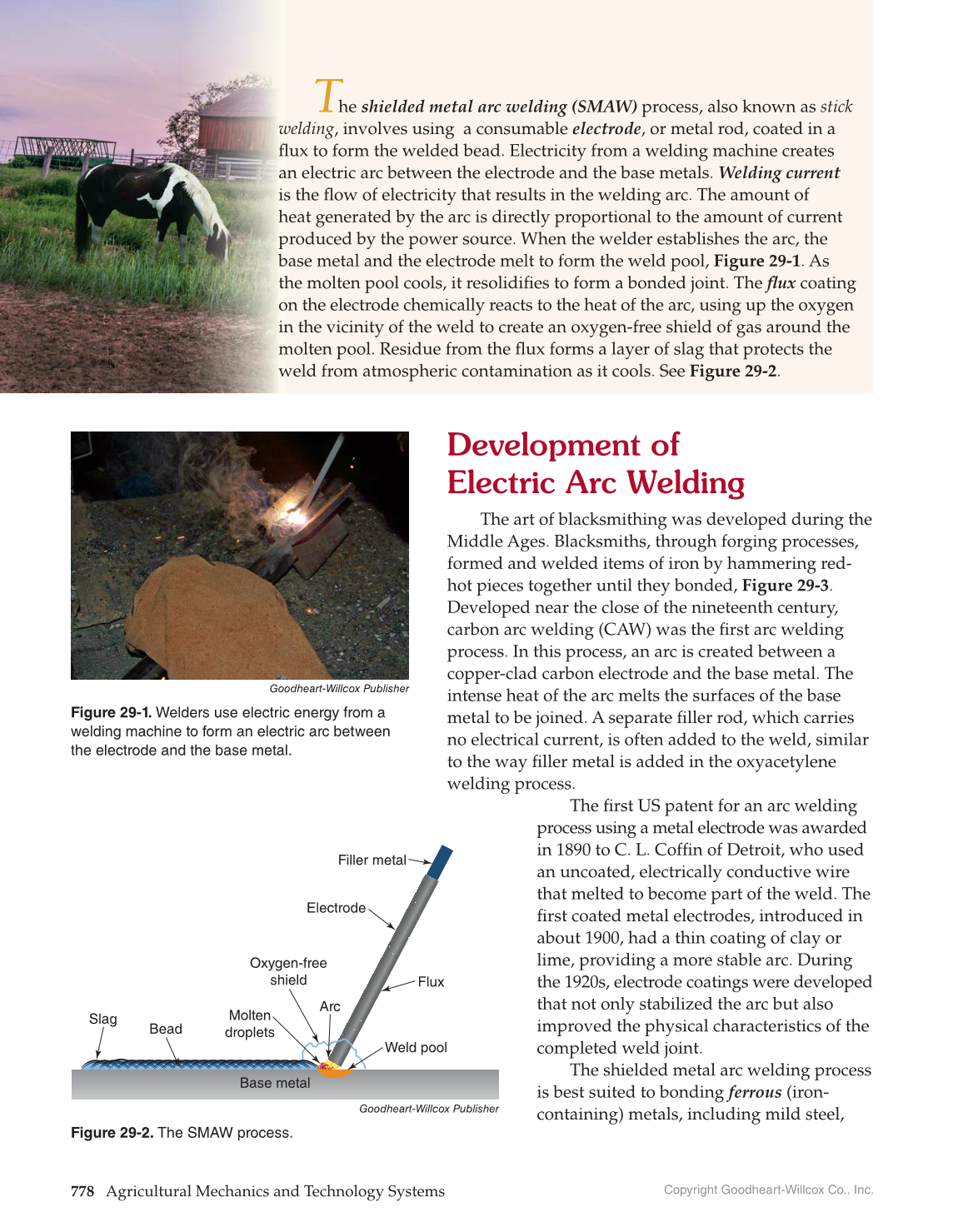

Filler metal

Electrode

Flux

Weld pool

Molten

droplets

Oxygen-free

shield

Slag

Bead

Arc

Base metal

Goodheart-Willcox Publisher

Figure 29-2. The SMAW process.