Chapter 3 Introduction to Basic Electrical Circuit Materials 55

equivalent, compute the square/rectangular conductor’s

area in square mils and then divide that area by 0.7854.

For example, if a 1" by 1/4" bar of copper is to be

used as a conductor, first convert the inch measurements

to mils (1" = 1000 mils and 1/4" = 250 mils). Then

multiply the dimensions in mils to get the area in square

mils (1000 250 = 250,000 sq. mils). Finally, divide the

square mil area by 0.7854 ( 250,000/0.7854 = 318,309).

This results in the original 1" by 1/4" copper bar having a

surface area equivalent to a round conductor of 318,309

cmils.

Wire charts commonly express the electrical values

for conductors solely based on their size in cmils. To deter-

mine the current carrying capacity, or resistance value, of

a rectangular conductor, the rectangular conductor must be

converted to circular mils.

Conductor Insulation

Materials with only a few free electrons do not con-

duct electrons well. These materials are called insulators.

To keep the electron flow contained to the conductor

path, and to prevent contact with other conductors and

people, conductors are coated. This protective coating is

called insulation. As the name implies, insulation is

made of insulating material such as rubber, plastic,

or other synthetic materials. There are many types

of insulation commonly used today. These materials

include thermoplastic, neoprene, TeflonTM, nylon, and

polyethylene.

The type of conductor insulation is determined by

the application of the electrical system. In determining

insulation type, many factors must be taken into consid-

eration. Some questions one might ask would include:

• Will the insulation be exposed to extreme heat gen-

erated by an industrial furnace or the extreme cold

of a freezer in a food processing plant?

• Will the insulation need to withstand exposure to

the acidic vapors in a chemical plant or to wet,

acidic soil?

• Will the cable be exposed to oil from manufactur-

ing equipment?

• Will the insulation give off toxic fumes if burned?

Resistance ohms per

Gauge Diameter Circular 1000 ft. at 25 C (68°F)

no. mils mil area copper wire aluminum wire

4/0 460.0 211,600 0.04901 0.07930

3/0 409.6 167,800 0.06182 0.1000

2/0 364.8 133,100 0.07793 0.1261

1/0 324.9 105,600 0.09825 0.1590

1 289.3 83,690 0.1264 0.2005

2 257.6 66,370 0.1593 0.2529

3 229.4 52,640 0.2009 0.3189

4 204.3 41,740 0.2533 0.4021

5 181.9 33,100 0.3195 0.5072

6 162.0 26,250 0.4028 0.6395

7 144.3 20,820 0.5080 0.8060

8 128.5 16,510 0.6405 1.016

9 114.4 13,090 0.8077 1.282

10 101.9 10,380 1.018 1.616

11 90.74 8234 1.284 2.04

12 80.81 6530 1.619 2.57

13 71.96 5178 2.042 3.24

14 64.08 4107 2.575 4.08

15 57.07 3257 3.247 5.15

16 50.82 2583 4.094 6.50

17 45.26 2048 5.163 8.18

18 40.30 1624 6.510 10.3

19 35.89 1288 8.210 13.0

20 31.96 1022 10.35 16.4

21 28.46 810.1 13.05 20.7

22 25.35 642.4 16.46 26.2

23 22.57 509.5 20.76 32.9

24 20.10 404.0 26.17 41.5

25 17.90 320.4 33.00 52.4

26 15.94 254.1 41.62 66.4

27 14.20 201.1 52.48 83.2

28 12.64 159.8 66.17 106.0

29 11.26 126.7 83.44 131.0

30 10.03 100.5 105.2 168.0

31 8.928 79.70 132.7 212.0

32 7.950 63.21 167.3 262.0

33 7.080 50.13 211.0 333.0

34 6.305 39.75 266.0 422.0

35 5.6 31.52 335.0 536.0

36 5.0 25.00 423.0 671.0

37 4.453 19.83 533.4 ____

38 3.965 15.72 672.6 ____

39 3.531 12.47 848.1 ____

40 3.145 9.88 1069 ____

Figure 3-3. Wire chart.

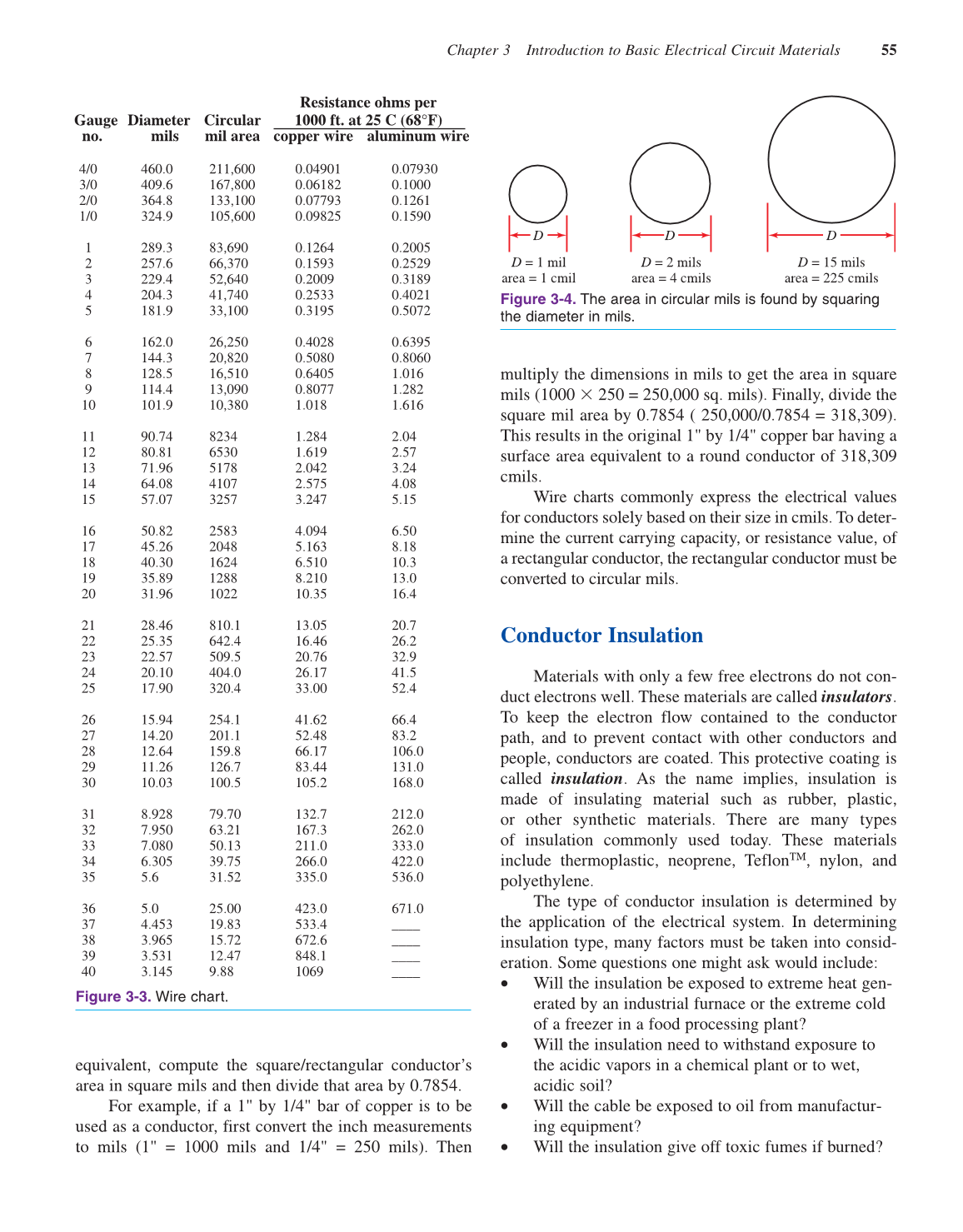

D = 1 mil

area = 1 cmil

D = 2 mils

area = 4 cmils

D = 15 mils

area = 225 cmils

D D D

Figure 3-4. The area in circular mils is found by squaring

the diameter in mils.