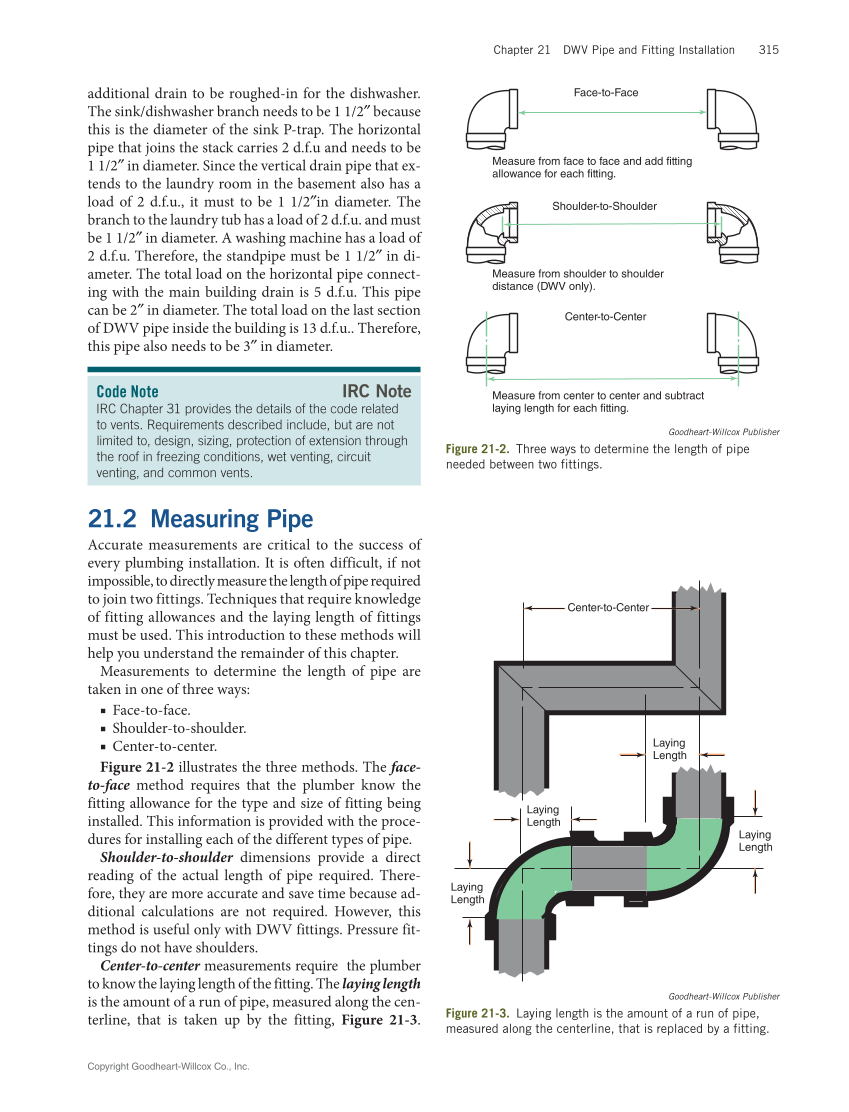

Copyright Goodheart-Willcox Co., Inc. Chapter 21 DWV Pipe and Fitting Installation 315 additional drain to be roughed-in for the dishwasher. The sink/dishwasher branch needs to be 1 1/2″ because this is the diameter of the sink P-trap. The horizontal pipe that joins the stack carries 2 d.f.u and needs to be 1 1/2″ in diameter. Since the vertical drain pipe that ex- tends to the laundry room in the basement also has a load of 2 d.f.u., it must to be 1 1/2″in diameter. The branch to the laundry tub has a load of 2 d.f.u. and must be 1 1/2″ in diameter. A washing machine has a load of 2 d.f.u. Therefore, the standpipe must be 1 1/2″ in di- ameter. The total load on the horizontal pipe connect- ing with the main building drain is 5 d.f.u. This pipe can be 2″ in diameter. The total load on the last section of DWV pipe inside the building is 13 d.f.u.. Therefore, this pipe also needs to be 3″ in diameter. 21.2 Measuring Pipe Accurate measurements are critical to the success of every plumbing installation. It is often difficult, if not impossible, to directly measure the length of pipe required to join two fittings. Techniques that require knowledge of fitting allowances and the laying length of fittings must be used. This introduction to these methods will help you understand the remainder of this chapter. Measurements to determine the length of pipe are taken in one of three ways: ■ ■■ Face-to-face. ■■ Shoulder-to-shoulder. ■ Center-to-center. Figure 21-2 illustrates the three methods. The face- to-face method requires that the plumber know the fitting allowance for the type and size of fitting being installed. This information is provided with the proce- dures for installing each of the different types of pipe. Shoulder-to-shoulder dimensions provide a direct reading of the actual length of pipe required. There- fore, they are more accurate and save time because ad- ditional calculations are not required. However, this method is useful only with DWV fittings. Pressure fit- tings do not have shoulders. Center-to-center measurements require the plumber to know the laying length of the fitting. The laying length is the amount of a run of pipe, measured along the cen- terline, that is taken up by the fitting, Figure 21-3. Code Note IRC Note IRC Chapter 31 provides the details of the code related to vents. Requirements described include, but are not limited to, design, sizing, protection of extension through the roof in freezing conditions, wet venting, circuit venting, and common vents. Measure from face to face and add fitting allowance for each fitting. Measure from center to center and subtract laying length for each fitting. Face-to-Face Measure from shoulder to shoulder distance (DWV only). Shoulder-to-Shoulder Center-to-Center Goodheart-Willcox Publisher Figure 21-2. Three ways to determine the length of pipe needed between two fittings. Laying Length Laying Length Center-to-Center Laying Length Laying Length Goodheart-Willcox Publisher Figure 21-3. Laying length is the amount of a run of pipe, measured along the centerline, that is replaced by a fitting.