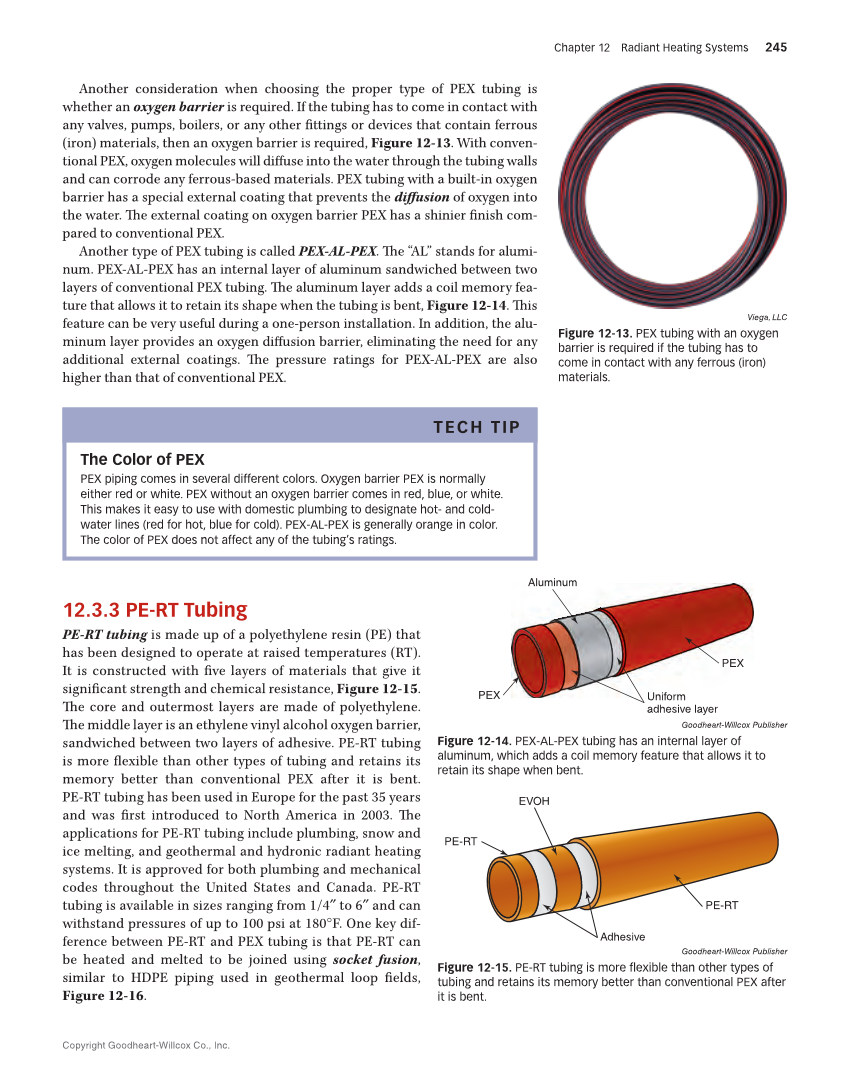

Copyright Goodheart-Willcox Co., Inc. Chapter 12 Radiant Heating Systems 245 Another consideration when choosing the proper type of PEX tubing is whether an oxygen barrier is required. If the tubing has to come in contact with any valves, pumps, boilers, or any other fittings or devices that contain ferrous (iron) materials, then an oxygen barrier is required, Figure 12-13. With conven- tional PEX, oxygen molecules will diffuse into the water through the tubing walls and can corrode any ferrous-based materials. PEX tubing with a built-in oxygen barrier has a special external coating that prevents the diffusion of oxygen into the water. The external coating on oxygen barrier PEX has a shinier finish com- pared to conventional PEX. Another type of PEX tubing is called PEX-AL-PEX. The “AL” stands for alumi- num. PEX-AL-PEX has an internal layer of aluminum sandwiched between two layers of conventional PEX tubing. The aluminum layer adds a coil memory fea- ture that allows it to retain its shape when the tubing is bent, Figure 12-14. This feature can be very useful during a one-person installation. In addition, the alu- minum layer provides an oxygen diffusion barrier, eliminating the need for any additional external coatings. The pressure ratings for PEX-AL-PEX are also higher than that of conventional PEX. 12.3.3 PE-RT Tubing PE-RT tubing is made up of a polyethylene resin (PE) that has been designed to operate at raised temperatures (RT). It is constructed with five layers of materials that give it significant strength and chemical resistance, Figure 12-15. The core and outermost layers are made of polyethylene. The middle layer is an ethylene vinyl alcohol oxygen barrier, sandwiched between two layers of adhesive. PE-RT tubing is more flexible than other types of tubing and retains its memory better than conventional PEX after it is bent. PE-RT tubing has been used in Europe for the past 35 years and was first introduced to North America in 2003. The applications for PE-RT tubing include plumbing, snow and ice melting, and geothermal and hydronic radiant heating systems. It is approved for both plumbing and mechanical codes throughout the United States and Canada. PE-RT tubing is available in sizes ranging from 1/4″ to 6″ and can withstand pressures of up to 100 psi at 180°F. One key dif- ference between PE-RT and PEX tubing is that PE-RT can be heated and melted to be joined using socket fusion, similar to HDPE piping used in geothermal loop fields, Figure 12-16. TECH TIP The Color of PEX PEX piping comes in several different colors. Oxygen barrier PEX is normally either red or white. PEX without an oxygen barrier comes in red, blue, or white. This makes it easy to use with domestic plumbing to designate hot- and cold- water lines (red for hot, blue for cold). PEX-AL-PEX is generally orange in color. The color of PEX does not affect any of the tubing’s ratings. Viega, LLC Figure 12-13. PEX tubing with an oxygen barrier is required if the tubing has to come in contact with any ferrous (iron) materials. PEX Uniform adhesive layer Aluminum PEX Goodheart-Willcox Publisher Figure 12-14. PEX-AL-PEX tubing has an internal layer of aluminum, which adds a coil memory feature that allows it to retain its shape when bent. PE-RT EVOH PE-RT Adhesive Goodheart-Willcox Publisher Figure 12-15. PE-RT tubing is more flexible than other types of tubing and retains its memory better than conventional PEX after it is bent.